(first posted 12/14/2012) I’m going to stick my neck out and argue that if there had been no computers in 1965, there would have been no Mustang. As Jim pointed out, a great part of Mustang’s excitement and success was its extreme customizability. You could order anything from a stylish economy car to a cut-rate T-Bird to a racing machine, just by choosing from its huge set of options. Why couldn’t you do that before? How was it possible for Ford’s factories to deal with all that? Computers, that’s how.

“You can make yours a family Mustang, a sports Mustang, an all-out luxury Mustang, or your own personalized version with a little of each.” Used to be there were just Fords, maybe five or six bodies, a dozen colors inside and out, six or V8, stick or automatic, radio and heater, and that’s about it. Odds and ends like windshield washers went in at the dealer.

Imagine you’re a clerk in the scheduling dept. of Ford, with piles of orders in your in-basket, each with different combinations of over seventy options. How do you make up all the engine orders? If a big engine is ordered, other parts and options must be included or prohibited, maybe different A/C compressor brackets, but no A/C allowed on the big engine with the optional towing package. That affects transmissions, springs and tires.

Now think of the production line. Maybe a car has a vinyl roof, maybe not. Do you stop the line if it does or do the cars in batches somehow? How about with and without power steering, batch those too, now we have four kinds of batches! Which kind of lights? Which radio, and how many speakers? Henry said “any color so long as it’s black” because that’s the only color that would dry fast enough to keep the line moving. That’s a far cry from all this – how to keep that line moving?

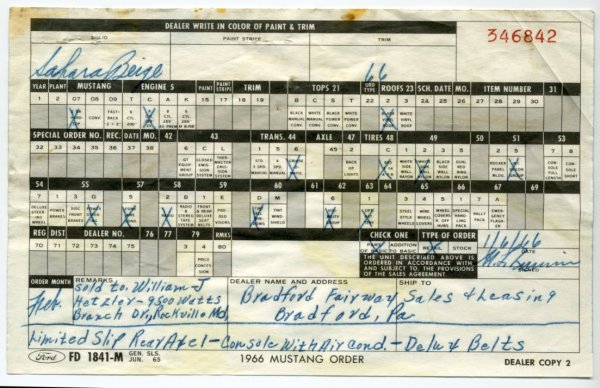

In Jaunary 1966, a man went into a Ford dealer in Bradford, Pa., and ordered a 1966 Ford Mustang hardtop in Sahara Beige, nicely optioned as a junior T-Bird set up for winter weather: the base 289 V8, automatic, limited-slip rear end and the bigger battery, with power steering, air conditioning, radio, a black vinyl roof, tinted windows, the “interior decor” and “visibility” groups, nicer seat belts and whitewall tires. His salesman filled out this order sheet, which I found at early-mustang.com, and sent it off to the factory. Take a close look at the order sheet’s entries: they’re numbered, either per box or small group of boxes, from 1 to 80.

Believe it or not, people once communicated with computers by punching holes in pieces of cardboard. All the order sheets from all the dealers were “keypunched” by nice young ladies like these. (Men did not touch keyboards in those days, typing was “women’s work”. There were no boys in my school’s typing class, we had metal shop.) They entered the codes from order sheets onto 80-column punched cards, that Ford called “Vehicle Order Cards”, seen in the first photo. For example, the “ROOFS 23” order sheet entry means punch the pattern of holes for a “2” in column 23 for a black vinyl roof, or “3” for white, or leave it blank for no vinyl roof. The woman at the right is keypunching the cards, the one at left is typing the same codes into a verifier that checks the card for errors.

Here is an IBM 7094 mainframe computer in 1965. It had all the same components as the computer in your pocket, input, storage, processing and output, though it ran a thousand times slower than yours and cost several million dollars. They’d load a deck of, say, a day’s worth of Vehicle Order Cards in that card reader on the right and send their input to the computer, which kept its programs and data files, like previous VOCs, on those big tape drives. Programmers figured out how to get the computer to do all that production planning, figure out what to order from suppliers, what parts needed to be where at what times. Finally it printed out all these orders and build sheets on fanfold paper in the printer on the left. Clerks carried them to the material and production departments, and the assembly lines.

Here’s a build sheet for the Trim and Chassis line, from Marti Auto Works. Printed at high speed by the mainframe computer, it says which parts to pick for its car. Check out the front and rear springs, they come in colors like golden brown and yellow-orange. New undercarriage styling? No, springs with different rates and such looked the same, so they were color-coded with dabs of paint.

Here’s our Sahara Beige ’66 Mustang on its way to its happy owner, just as he designed it. No other car exactly like his! He doesn’t know it, but he and his car have entered the Silicon Age.

I scooped these cards and sheets and info up out of pretty skimpy Internet data about this. I’m sure some of you know a whole lot more about this, maybe even first-hand. Please tell us in the comments!

Mike-

I think you’ve done a great job of covering the subject, but here’s a couple more facts on the topic:

1) The build sheet was often placed in the completed car, either under the carpet or stuffed into the springs on the underside of a seat cushion. Restorers love to find these documents, since it provides them with a blueprint describing the original vehicle color, trim and options prior to thirty years of use and abuse.

2) A metal tag called a “buck tag” was also riveted or tack welded to the body, typically in the engine compartment. The buck tag condensed the build sheet information into simple alphanumeric codes. This provided a quick reference for things like engine and transmission packages for the line workers. I’ve attached an example of a buck tag image, with thanks to the website foureyedpride.com (a Fox body enthusiast site).

Us IH guys have it good, On the full size vehicles a mini copy of the LST or Line Set Ticket is taped to the back of the glove box. It includes all the equipment on the truck. On the Scout it varries depending on year. On some of the Early Scout II it was a sticker under the hood and unfortunately they didn’t last in that environment. Later models had it affixed to the glove box door.

Even if it is missing we can still order a copy produced off the microfiche from the Wisconsin Historical Society whom Navistar transfered the older records to for archiving after the person who had been maintaining the archive retired.

The LST traveled down the line while the workers checked off installing the components, a copy was made for the records and to make the sticker or small copy and the original was put in the glove box.

Here is one that a owner recently ordered

With IH, the build sheet was crictical when ordering replacement parts. If you view a blow up of that build sheet, the actual part number is listed to the right of the option description.

Back when I worked in fleet shops, the parts department always had a copy of the build sheet for each IH truck by VIN. The couterperson pulled the sheet out every time I ordered a replacement part because International would use different components even on ten trucks built to identical specifications.

For example, the brake system on one truck might have a twenty gallon air tank, and two ten gallon tanks on a second truck. I think the production line mixed and matched components present in the building to meet the specification and get the order out the door (at least for their medium duty trucks).

Yes having the LST is critical in many situations but it was because each truck is special ordered if it is typed on the sheet that is the way the truck was ordered for what ever reason. Now if something has been clrossed out in pen and another part number written in that line then they used what they had. I’ve seen more than a couple copies of LSTs like that for light line trucks.

I tried bringing that up awhile back, and an ardent IH fan stuck his fingers in his ears and went “LA LA LA LA I CAN’T HEAR YOU LA LA LA LA IS NOT IS NOT IS NOT LA LA LA LA!”.

Imagine my surprise finding one of these while removing the clock on an old Travelall at the scrapyard! It was just as you said, taped to the top of the cardboard glove box: my victim was highly optioned.

I have searched for these since then but have yet to find another. What years did IH do this? Were these vehicles built at more than one assembly plant? I know that build sheet placement differs widely between each assembly plant.

As far as I know the full size trucks had the mini copy taped to the back of the plastic glove box on all 1969 to 1975 full size (you can tilt it open, release the clips and it will tilt out to reveal it) and on the top of the cardboard box for the 1961-1968 models that you must remove to find. There was only one US production line for the Full size trucks, in some years they did build some light line trucks in Canada too.

You have made me slightly more dangerous: thanks!

Since the vehicle pool I obtain these from is literally days/hours away from being recycled & generally not available to the public, I’m not stealing anyone’s joy by robbing all the available documentation I can find.

I was under the dash surveying the extensive rust damage on our auction-impulse-buy ’67 Mustang & found its buildsheet folded and taped around the car’s main wiring harness — it was “right there” close to the ignition switch amazingly enough. I hadn’t even bothered searching for one since the car’s interior was completely replaced at some point.

Careful surgery on the tape (not so much for my abbreviated pinkie!) got me what you see below.

It took probably twenty minutes to unfold the thing without shattering the brittle paper. Some of the bottom had been torn off at one point but about 75% of it survived. Neat.

Of course this car is too far rusted to be fixed & will be used for the “better” ’67 project car…which of course has no build sheet on its wiring harness.

On these Mustangs the build sheets aren’t the only way to prove the originality because of Kevin Marti — he has complete build info on every ’67 Mustang produced. We got a full report on our “better” ’67 Mustang along with a 100% legit door trim tag for just over $60.

Note the hood on this picture is some other vehicle parked nearby.

I went to purchase a new car in January of 2001. I sat with the saleswoman and detailed the exact combination of features colour model etc. that I wanted. She excused herself and came back quite excited, telling me that she had located exactly the car that I wanted at a dealer some 250 miles away and that I could have it within the week. I had to tell her that I was not interested in a car that had been sitting out in winter weather for god knows how long. I wanted one fresh from the factory. She left to check with the sales manager to see if that could be done and I told her that if it could not be done that I would be walking. When she came back she told me that they would do it. As it transpired, my car was ordered in January, built on the 16th of February and I took delivery in early March. I do not have a lot of new car buying experience as I still have this car and it is still pretty much as new as I never drive it in winter weather, and over maintain it. I do wonder If this is common now. Is it really a struggle to place a real factory order like in earlier times these days?

Not sure about U.S.-based makes, but a doctor friend of mine tells me that the last few BMWs he’s bought have all been built to order, and yet they’re not particularly rare or exotic (the last two were 5-series). In fact, for the last one he placed the order and was told there was already one in the queue, and he could still choose the paint and leather colors, and the wood trim. No kidding, he got the German-built car in two and a half weeks! Wouldn’t have believed it had I not been around him throughout the process.

I’ve since seen some others on TTAC confirm that this is fairly common for BMW, and some of the other German makes, as well.

My 2001 Subaru Impreza L wagon was a custom order, although most of the options could have been dealer-installed. Non-standard items on mine were roof rack, fog lights, alloys (almost unknown on this model at the time), manual trans and various bits of interior and exterior trim. No one at the dealer kicked up a fuss over the special order. Four weeks from order to delivery.

What you’re describing used to be common (when I was a kid). Nowadays, to keep the factories running, cars and built and stocked at the dealer, and of course the dealer wants to sell something he already had, if not that then something he can trade another dealer for, anything other than ordering an additional car to what he’s already got floorplanned.

A lot of this change started in the 70’s when the imports started gaining large market share. Of course, you can’t really multi-option something that’s low priced and coming from Japan, so buyers got used to small amounts of options and taking what was on the lot.

And of course, once that set in, the American brand dealers were more than happy to follow suit. Anything to move what’s on the lot, just convince the customer that custom ordering isn’t possible, or at least ridiculously difficult. Why go to the extra work, if you can make the sale simple (for the dealer)?

in 76-78 Oldsmobile’s advertising slogan was “Can we build one for you?” which was changed to “We built one for you” for 79.

Well for many people, the car on the lot is just fine and dandy, remember if your car was stolen or totaled, you needed something right away. If you were just looking for a Chevy sedand with an automatic and a V8, you probably would be happy with something on the lot.

Japanese cars of the 1970s were well-equipped, and not available in many colors. This was considered to be a selling point, as domestic cars of that time, especially compacts and subcompacts, were truly stripped in unoptioned form.

The first Honda Accords, for example, were available in three metallic colors – silver, gold and light blue – and one body style (a three-door hatchback).

After choosing the color, the main question was whether you wanted the manual transmission or the Hondamatic.

But every Accord also came with nice upholstery, full carpeting, alloy wheels, coin boxes and a radio, all as standard equipment.

Somehow I’m picturing a diner;

Customer; “Blue, manual, no A/C please.”

Salesman: Comin’ up! (shouts to back room) “Ty-D-Bowl sweatbox with a fun pedal!”

I think the accords you are describing had painted steel wheels, not alloys. At least my 1979 did.

Indeed, alloys were a (high-profit) dealer installed accessory.

I custom-ordered a 1997 Jeep Wrangler, the dealer seemed to think this was normal. 2.5L engine, 19 gallon tank, leather steering wheel, cassette stereo, sound bar (overhead speakers), grey vinyl seats.

It was fun for a while. I once drove it from Boston to San Francisco and back.

Strangely, the squishy soft vinyl seats in this car are the only ones I’ve ever found that give enough support to my right leg so it doesn’t hurt after an hour or two, which happens in every other car I’ve ever driven, including various BMWs (7, 5, 3, X3) and Hondas.

On the other hand, the noise from the soft top was hell on the freeway.

Wrangler buyers are old school traditionalist as a group. The TJ Wrangler darn near violates the Geneva convention with high levels of NVH.

My dad ordered his cars for the longest time, because he wanted literally a plain-vanilla car. White, 6-cylinder, three-on-the-tree, radio and heater, and that was it. Dealers really wanted their in-stock cars to have stuff like automatic and power steering. Okay, the ’64 Mercury had the 390 V-8, automatic, and power steering, but those were all standard on Mercurys (our Monterey really was a stripper by Mercury standards). Dad’s first bought-off-the-lot car was our ’69 Dodge Monaco, on which he got a pretty good deal, and which had such luxuries as air conditioning, power windows, and a reclining passenger seat.

When I worked at Ford, the management lease cars were by definition built to order, so I could indulge my passion for checking every box on the order form and get my preferred color and interior.

Interesting your school had shop for the guys while the girls took typing. When I was in 8th grade, everyone took a half year of typing and a half year of art. The typing wasn’t because any of the guys were going to be secretaries, it was because most of us would be going to college, where knowing how to type would be a big advantage in preparing papers for classes. In our school, guys took a half year of wood shop and a half year of mechanical drawing in 7th grade and a half year of metal shop and another half year of drawing in 8th, while the girls took home ec both years.

Is it even possible to custom order a new car anymore? Serious question.

Yes. And in many cases, but not all, a dealer would prefer to order something for a customer rather than screw around driving to other dealers, exchanging checks and other paperwork, making sure no damage occurs while driving back and forth, making sure all the equipment is there (floor mats, headphones for dvd players, etc.) Besides the customers love ordering a bespoke vehicle and it can bring a good Customer Satisfaction Survey, which is huge in itself.

Well define “custom”.

Back in they day you could for example spec a color that was not available on your car normally by following the right procedure and greasing the wheels properly, my Estate Wagon is a Riviera Silver Blue, normally a Riviera only color, but it was painted on my wagon at the factory since it was requested as a special order car, this was rare, but not uncommon at GM, Pete Estes, head of Chevrolet had a Z/28 convertible painted a Cadillac color I believe, a friend of mine has a 1967 GS 400 in a non-standard interior and exterior trim combo, not available according to the Buick color guide for 1967, but its there on the car and on the Fisher Body trim tag.

Thats pretty much long gone, though when I sold and ordered Buicks through the late 90’s there was a slightly scary “trim compatibility overide” order option that would allow you to build a car in a color combo that only The Joker would have loved, green car with burgandy leather, for example, now I never ordered such a car, but I recall the option being there. SEO was another “custom color” option, but you had to order a certain number of cars to get something like that, say a municipality that had blue and yellow water & sewer trucks for example, or police cars.

I’ve also seen a few mid 70’s Cadillacs with special order contrasting piping on their leather seats, its noted on the window sticker as “SR” for special request.

Though there we oddities with that too, I recall taking in a 1990 or so loaded up Chevrolet C1500 SIlverado Z-71 in on trade, it was normal, except that it was painted flat beige, a color not available on a non-fleet truck, something that shouldn’t have existed, since this was a nice spec’d out truck, not your average fleet longbe, but there it was. Maybe a fleet manager got cute somewhere.

Today there are so few variations that you would be hard pressed to not be happy with something on the lot of a larger dealership, take a Camaro for example, something available from a base $24K V6 to a $61k ZL1 convertible, with a large range inbetween, but a large dealership would have almost any version that you would want on the lot.

Heres a shot of a window sticker showing the “SR” seat piping.

And a picture of the interior……

Ah – for the days when you had interior colour choices. Nearly all of the Hondas I see are the same grey – I don’t think they even offer a choice on some models. Even if a choice is available, many have standard black or grey dash/steering wheel/doors anyway so you really only get differentiation on seats and door inserts.

The upper league Germans still seem to offer choices and if you want customisation they have Designo (Mercedes) or Individual (BMW) packages that really let you run riot! I ordered a BMW 640i Gran Coupe and received it last August. I went for an individual interior with extended leather in Merino Havana brown leather. Man that leather is everywhere! Seats, console, doors, dash – even dashbtop (but that is black). Genuine customisation!

The mom of one of my friends was color blind and ordered a Dodge Charger in gold with a blue interior. Im sure the dealer got a big deposit from her before checking the special box on the order form and sending it in.

Strange question, but if he was color blind, why did he care what color his car was?

It distorts colors. Its not like the world looked black and white to her.

I knew a guy who drove a fuchsia (think really hot pinkish purple) Neon. We were talking about it and he told me that when he was shopping, he told the salesman that color didn’t matter because he was colorblind. The salesman called the next day and said he had a Neon he could make a good deal on. My friend asked “what color is it?” “It’s Magenta.” My friend asked “what is magenta.” The salesman replied “it’s a kind of a red”. My friend didn’t care and bought the car.

How about this color, called “Clear Blue Sky”. It’s Rust Oleum from Lowes !

Not only is it possible, dealers love ordering new cars, but the reason is somewhat sinister. When someone orders a car, that dealer has ‘locked-in’ that sale, essentially taking the buyer off the market. The only determining factor is how long the buyer is now willing to wait before they finally get fed-up and cancel the order.

The clincher is that, nowadays, ordering a car requires a non-refundable deposit. That means if a buyer decides to cancel an order for a car that’s taking too long, well, they lose that deposit (and sometimes dealers even require the car to be outright completely purchased before they’ll order a car).

To a certain extent, it’s understandable. As Carmine would seem to imply, few dealers are going to order an essentially unsellable vehicle in a Joker-level color scheme without it being completely paid for first. It’s insurance against being stuck with a car that has such a bizarre color scheme and/or set of options, in the parlance, ends up being ‘welded to the showroom floor’.

-Some states don’t allow nonrefundable deposits. All manufacturers should be able to give retail customer special orders build priority over cars built on spec.

-How can any color scheme be Joker level when the only interiors on offer are black or pale greige?

” All manufacturers should be able to give retail customer special orders build priority over cars built on spec.”

nonsense. if you special order a car, it gets built just like any other one. that’s why orders typically take 6 weeks. it doesn’t take that long to build the car, the manuf. usually has 4 weeks of production already lined up, and your order has to wait for the next rotation to be scheduled. And I can guarantee you practically nobody in the assembly plant knows which cars are customer orders or dealer stock orders.

I really wish we would see a return to a the time when ordering the car you wanted was the norm. Looking for new cars I can never find the exact combination I want and most dealers just don’t want to order one. If you can find a dealer that will order one the wait time can be quite long. Plus all the incentives always say must take delivery from dealer stock. What really kills me is when you find a dealer that has 3,4 or more that are identical. When we were looking for a minivan there was one dealer that had somewhere near 30 absolutely identical vans out of the 40 or so they had.

Oh, it’s still possible, but you’re going to pay through the nose for it. High-end German cars, in particular, still have quite a number of a la carte options. Just check out what’s available on a new Porsche 911 sometime. The sky is the limit, but if you want something truly invidualistic, you’re going to have one extremely expensive Porsche.

When I bought my first car after retirement, I didn’t have any problem finding a car that was spec’d out the way I wanted. The problem was the color. About 90% of the cars on the lot were either silver, gray, or white. As it turned out, I got lucky and a blue one with my option content arrived on the transporter at just the right time.

Same experience here, except I did get stuck with a silver car. I wanted a standard transmission and told the salesman I would take any color as long as it was a COLOR. I didn’t want white, black or silver.

Well, the dealer didn’t sell a lot of manuals, so there were only a few on the lot and only one with the trim level I wanted. It was silver, of course.

I didn’t fight it. I could understand from the dealer’s perspective, if you’re going to order a few cars with an unpopular transmission choice, you’re going to order it in the most popular and unobjectionable color so that you don’t get stuck waiting for the one buyer who wants both a standard tranny and crossing-guard yellow paint.

When my daughter bought her (used) yellow pearl manual Honda Jazz, we had to make a 300km round trip to a dealer who had one in stock. The price had just been reduced by $2500 as they’d had it on the big city lot for six months! What’s not to like about a pearl yellow manual Jazz?

The body colour ?

I agree. When I was about fourteen or fifteen, the Monte Carlo SS had just come out and a girl down the street ordered one. I remember months going by before it showed up in her driveway.

The last time I got the new car bug was somewhere around ’99 or so when the Mustang had been restyled. I loved the new green they offered & saw a convertible with white leather interior. It was just enough to get me to the Ford dealership. I thought a new 5-speed green GT with white interior would be a neat car to have.

“Hi”.

“Hello there, may I help you?”

“Yes, I like the new Mustang GT and was wondering if white interior was available on the coupe.”

“No, sorry, only on the convertible.”

“Really? No special order or any way to get around that? I’m seriously thinking about one of these cars but it has to have white interior”.

“No, no way around it, sorry.”

“OK, thanks. Bye.”

“Sorry.”

“That’s okay”.

In my checkered past I did a short stint as a car salesman. Most people don’t want to wait for a car, and most don’t want to pass up any incentives that may be offered.

Multiple options greatly increase the cost of manufacturing. Most people can be satisfied with relatively few choices and option “packages”. The Mustang may have given you several engine/transmission choices, as well as a dozen colors for the exterior and at least half a dozen for upholstery. Today most cars have about half a dozen exterior colors (if you count beige and silver-beige as two colors) and usually 3 interiors; Charcoal gray, black, and some variation on tan. Engine options are often just two, sometimes 3 choices. And of course many cars are not really available with a manual trans. The Japanese makers seem to have figured this out long ago. Choose a trim level – basic, deluxe, super deluxe.

Going back just a bit, to 1957 – http://www.1957ford.com/interior/index.html – take a look at the different colors and color combos, and all the different upholstery materials/colors. I don’t know if you could spec your ’57 with any combo you wanted – I don’t think so as some upholstery fabrics were only for certain models, Custom, Fairlane, Ranch Wagon, etc. Different combos were available for sedans, 2 doors, wagons. Consider all the combinations that Ford had to keep track of and organize. And what was the state of computer tech in 1957?

Comparing color and equipment choices in 1957 to now disproves the whole premise of this thread. There were IBM and competing card tabulating equipment used to run businesses decades before they used electronic digital computers.

BTW, the build sheet for my 1971 Chevy truck was tucked in the seat springs. That truck was a real fleet “stripper”. No radio, not even a rear bumper or spare wheel and tire. The same information was in the form of a glovebox sticker in my ’93 (which I special ordered).

A couple of things to keep in mind was back then it was not uncommon to build a million of a give car line in a year. So it didn’t really cost extra to have all those options, there likely would be enough of even the unpopular combos to still be profitable. Plus it was the norm to order the car you wanted not take one of the demos on the lot, so they didn’t have to worry about getting stuck with an oddball car, the dealer ordered or was plused out the safe common combos as spec units and then the person ordered the less conservative combos. Plus back then it truly was just in time production not just in time deliveries as is done today. Get an order for the pink/grey/black interior, have the in house seamstresses make up a set and a set of seats and panels are ready to go for the car when it heads down the line in a couple of days. Nowadays it’s get an order of completed seats from a supplier that will cover this weeks planned production. Plus a lot of cars back then were produced in significantly higher numbers and often that meant multiple lines in multiple plants and multiple suppliers to meet the demand.

You are one of the very few lucky owners to find a build sheet in one of these trucks. They are nearly impossible to find as I have searched hundreds of these things!

Many of these trucks — even up to the 80’s were ordered without rear bumpers and/or radios. For example my heavily optioned ’78 Sierra Classic was ordered with neither: a Delco “look-alike” AM/FM was installed early on in its life & the truck had a chromed rear step bumper on it.

I don’t believe certain step bumpers were even available so the trucks were not ordered with any bumpers — the dealers had piles of chrome and/or step bumpers which they installed instead.

Color choices are simple. They only affect one stage of production, each color presumably took the same length of time on the line, and the only supplier effect is how much of which color to reorder. The most important fact is the color of the paint or upholstery has no effect on any other parts in the build.

Mustang had lots of interdependent options. Take another look at the build sheet above. Those are all mechanical parts, each with so many choices they had to be color coded. My favorite is “SPEEDOGEAR”. Think about how many combinations of engines, transmissions, rear end ratios, wheels and tires a Mustang could have. Ford had to work through all those for each car and choose the right gear for the speedometer to be correct.

People and card sorters could do that, sure, but at Mustang’s level of options and complexity, the cost of getting it right (and the cost of getting it wrong) was too high for a volume-priced car without computers. The genius of Ford’s people was to realize that once they had computerized the build process, they could afford to offer this exciting new “have it your way” type of car to a very broad market at a popular price.

That’s the funny thing about computers, and inventions in general. An existing thing gets better, and that’s good, but the real impact turns out to be new things that weren’t possible or practical before.

Just to give you an idea of the complexity, a four-cylinder Fiero could have one of four different springs installed at each of its four corners: application depended upon equipment combinations.

I know this was done back in the seventies as I’ve compared a lot of my GMAD buildsheets on identical year/models and noticed that for example…. one ’76 Monte Carlo with 350 engine may have an “XY” RR spring while another 350 Monte Carlo may have an “XZ” RR spring. (I made up the “XY” part since I don’t have the sheets in front of me).

Also, some GM cars had different left & right coil springs. One car could literally have a different coil spring on each wheel. I haven’t seen any of these although many build sheets I have call for one car to have three different type coil springs.

My 07 Honda Fit was built to order, but for a different reason than most. My wife insisted on beige interior, and that color only came with a white car in Sport trim. There was a waiting list for these cars in the summer of 2006 and the dealer had no such cars in stock and none coming.

We were kept advised of the car’s build date, ship date, port arrival date and I finally got a call that it was at the dealer. It was about a 4 month process, but mainly because the car was in such demand at the time that the dealer’s allotment was limited to a very small number of cars per month.

My mother always bought off the lot because she waited until summer and bought a car at the very end of the model year. My dad, on the other hand, got his cars in the fall and usually ordered.

My car-mentor Howard was a Mopar guy, who steadfastly refused to order. Build-quality varied so widely in the 60s-70s that he wanted to see what he was getting, so he always picked from the lot.

One of my favorite ‘punch-card’ stories involves the 1968 Plymouth Roadrunner. Initially creating the original set of cards for not only the options, but the basic way the car was to be built, was a time consuming process. The Roadrunner was based on the intermediate Belvedere line and used most of the same cards, but they had to be created and put in the correct order, replacing those cards for different components. For example, the Roadrunner used the same hood as the GTX, so the Belvedere hood card would be replaced with the GTX hood card in the Roadrunner stack.

When the Roadrunner was finally approved and the punch-cards were being created to determine how the car would be built, Dodge executives were offered the chance to have a duplicate set of cards created based on their intermediate-sized car, the Coronet. Like many others within Chrysler, Dodge thought the Roadrunner would be a flop and turned the offer down.

As you can imagine, when it became apparent that the Roadrunner was a hit and Dodge realized they wanted one, too, not already having their own set of Coronet-based punch-cards was a signficant reason the Dodge version of the Roadrunner (the Super Bee) would take another six months before it got to market.

It is interesting to see the level of option complexity has declined so much since those days, anything that doesn’t see significant volume is out. I wonder if it is because the design and validation process is now so over the top that simple mixing and matching now has to be fully tested etc for even the simplest variation. Not to mention you have to re-write the owner’s manual… And as described above, if you had the right connections you could get options or combos that technically didn’t exist.

It is just as common to order a car here as take one that is in stock, as dealers don’t carry the same number of cars as in the US.

I remember when the Omni America and Horizon America came out towards the end of their runs. The story from Chrysler was that the car could be priced so low partly because the car came in severely limited colors, trims and option packages. When there were very few variations, the manufacturing costs were so much lower. I recall reading somewhere that this is behind the restricted color and trim choices today. It evidently costs a lot of money (in cash and lost production efficiency) to change a spray booth from one color to another. Fewer colors mean fewer changes between colors, or possibly dedicated booths.

If sounds logical but, if correct, how is it that Fiat is able to offer the myriad color/interior options on the 500?

Is the Fiat 500 really all that cheap? The MINI, for example, isn’t exactly a cheap car, and certainly isn’t being pitched as an economy car. The Fiat 500 is being promoted as a chic car that happens to be small.

I don’t know that it is that difficult and/or expensive to change the colors in a spray booth, considering that most are not solvent based. IIRC, there was a show on one of the channels showing a Kia plant in Georgia that was equipped with a spray booth that could change colors almost immediately, and they ran several colors for the model being shown. It would seem that color is only a factor if you are selling style, thus the 500 comes in fun and funky colors to appeal to their market.

I think I read on here somewhere that the paint lines are flushed and changed in a matter of seconds now. Like 4 seconds. And it wasn’t much back in the late 60s. They try to lump same color cars together, but doesn’t always work. The spray equipment is flushed into drains in the floor and the next color is introduced. Possibly why there are so many variations on paint. If you’re painting one color, do a 4 second flush and then change to lighter color, seems to me that you new color will still have a little variation as the equipment gets the old color out and new color in.

Which comes first – white as the most popular color or the OEMs painting more white cars due to fleets and such? Fewer colors equals fewer changes on the line and more cars being made. Never mind the consumer may want a more colorful car.

I’ve also always thought a silver or gold car would make a good start for a “candy” paint job, if you happen to think that way. Especially on the used market.

I always thought that the limited selection of colors and options began with the original Honda Accord. It was only available in blue, silver, or brown and I believe the only options were an automatic tranny and a/c since the level of standard equipment was unusually high for the time.

A great piece, Mike, about one facet of these old cars that we never think about.

When I was a kid, my Uncle Bob got in on the ground floor of GM’s computerization process. He was at a plant in Defiance Ohio, IIRC, and took us in one Saturday to show off the computer. He grabbed a big stack of punch cards and fed them into a hopper, where they sorted themselves out into maybe a dozen different slots. I was about 7 at the time, and thought “that’s cool. But what good does it do?”

A guy I used to work with had worked in accounting at the Ford power steering plant in Indianapolis in the 60s. He recalled a day when there was a programmer who was doing some tweaks to the computer. He needed some punch cards for a test. He went into the huge room where dozens of ladies were typing out punch cards. He found an open keypunch machine and started pecking out his cards. The room suddenly went silent and the manager went racing into the keypunch room. The keypunch operators were union and the programmer was not. The manager grabbed the guy and told him that he would see that the guy got any cards he needed punched but please get the heck out of there.

Thanks, Jim!

Uncle Bob probably showed you a card sorter, which is not a computer but a stand-alone machine that sorts the cards according to some simple criteria you can set with switches and wires. Punched cards were used long before computers came along, for things like the census, and card sorters were used in many passes to sort for, say, left-handed Minnesotans over 40. Or vehicle order cards specifying the small-block V8 with automatic. With computers around they still used them for simple sorts that didn’t need to wait for expensive computer time.

Here’s a video of one running.

When you get right down to it player pianos used a very long punch card that had to be stored on a spool. The concept was just modernized and made more compact.

Yes indeed. And the player piano was probably inspired by the Jacquard loom, invented in 1804, that used a chain of punch cards to specify complex patterns in the fabric. Information processing machines go surprisingly far back in history.

Here is a story about the card sorter. My friends father was a senior guy with IBM an he explained how this business worked. IBM leased two different models of the sorter. Only difference was the speed at which they ran. There were two pulleys inside somewhere. If a customer upgraded to the faster sorter the technician just moved the belt on to the larger (smaller?) pulley and the machine ran twice as fast. IBM was raking it in in those days and pricing like that was part of how they did it.

IBM still has that racket going. If you want to upgrade your mainframe computer, they just dial in and tell it to run at a faster speed.

The Original SQL Server

And two weeks later, a Chevy dealer a thousand miles away scratched his head at the Chevelle Concours four-door hardtop in Evening Orchid with a green interior, 4-barrel 454, 3 on the tree, 2.73 non-Posi diff, AM/FM/8 track and heater delete that just came off the transporter…

Don K., you and I must have lived in a parallel universe. My dad custom ordered most of our family cars, a ’55 Oldsmobile 88, a ’59 Ford Galaxie, a ’63 Mercury Monterey Custom, and later, a ’77 Cadillac Coupe de Ville. Seemed like the regular course of buying a car to me, although I have a vague recollection that he may have paid a somewhat higher price to get what he wanted, forgoing any dealer discount for something already on the lot. He loved to haggle, though, so I’m sure he got acceptable deals. Seemed like dealerships were smaller back in those days, too, they just didn’t carry the huge inventory that you see now, and there wasn’t a lot of choice of cars already sitting there.

We, too, took a year of typing in the eighth grade. The class was full of boys, and you are exactly right, not because they were going to be secretaries, but because we were all college bound. I typed all my own reports and papers through graduate school on a Remington portable manual, and I can still type a mean streak to this day. We boys also took mechanical drawing, electric shop, wood shop, print shop, and metal shop, and yes, the girls were all taking two or three years of home economics (this was all in junior high school, grades 7, 8, and 9).

I learned about computers with the punch card system in college. We wrote our own programs, took them to the Computer Center, entered all the data on punch cards ourselves, turned them in to be run and printed out. And invariably they wouldn’t run correctly, you would have to go through several iterations to fix mistakes and get the program to come out correctly. Very time consuming, it was the bane of my college existence in the late ’60’s. Different world.

Interesting comment from David Skinner re the build sheets. I would often find those stuffed under the springs of the back seat (I was always pulling out the back seat to vacuum the floor underneath, being completely compulsive about car cleanliness). Never knew quite what they were, or what to do with them, so I would leave them there.

I also took typing as a college-bound boy, but was also allowed to take some shop as I wanted to be an engineer.

Working at Rockwell in the early 1980’s, we still used punch cards for the IBM mainframes.

I took typing in elementary school in the early ’80s because the parents had fundraised to get computers for the Catholic school and the nuns didn’t know what else to do with them!

Eventually the fresh-from-college-and-waiting-for-a-public-school-job new grads who made up the rest of the teaching staff introduced type-in programs and Oregon Trail…

As the resident build-sheet hoarder, I thank you for leaving the build sheets intact 🙂 I made copies of the one found in my first car & put the copies back between the seat foam & frame.

Buying a car in dealer stock will get you the discounts, they go out the window when you order one to your specs.

I wanted a Mercedes A class with a beige (tan) interior than the normal black . Delivery time .. 3 months!. ah .. normal for a German built car..

Here in the UK you wait for any new car. I heard of buyers being driven around a US dealer lot in a golf cart and picking out a new Accord from 70 of them!. True?.

Yes, some lots are quite big and have huge numbers of a particular model in stock. A local Dodge dealer has been touting that they have over 100 of the “hot selling” new Darts in stock (translation: we can’t give these things away). They also often have cars stashed elsewhere as they have too many to fit on the main lot.

Oh yeah, we had most of everything in stock for delivery.

Given the depreciation curve and company-car culture it’s surprising anyone in the UK buys new at all.

My Dad had ordered several of his cars, too. In 1977 he ordered a Caprice Estate Wagon, 6 passenger, loaded, but with very weird options. My brother was involved in the ordering so I knew it would be strange. It was brown with tan vinyl interior. The seat was not split but power so the whole thing moved when you adjusted it. It had power windows, locks, tilt, cruise, the old school digital clock, right hand remote mirror (which a lot of those huge cars did not have back then – surprisingly), a passenger lighted vanity mirror for my Mom, no bumper guards and strips (my brother said the bumpers looked better like that – weird) no rear defroster (again real smart for New England weather), a luggage rack and cool sport wheel covers. They were plastic and looked like mags. The only problem is they fell off constantly and my Dad decided to replace them with a set of the base hubcaps after 2 years. It had a horrible Delco AM-FM stereo, and my brother made sure it had the 350 V-8, heavy duty suspension and performance axle. It was a good running car but made like crap – it fell apart after a few years and was replaced with a 1982 Country Squire that Dad loved.

I’m surprised that a non-split power seat even existed for them. For that matter, did any of them have rear defrosters with the window winding down into the tailgate?

“Wierd options ” reminds me of my recently-purchased 77 Mercury Marquis. Base model, has fender skirts and bumper guards, but no vinyl roof. It has a radio and rear defroster but no clock. It has a tilt wheel but no power seat. It has cruise control but no power windows.

The presence of cruise is very odd in a base model. Its fairly rare, even many well optioned luxury Marquis models did not have it.

If I’m reading the punch card at top correctly, the buyer drove from Rockville, MD to Bradford PA…in the “wilds” in the northern part of the state, a good 200+ miles with no major highway connecting the two…to buy this ‘Stang.

Must’ve been a screaming deal. Or maybe not every Ford dealer was as conducive to custom-order as Bradford Fairway Sales & Leasing was.

Yep, that’s one hell of a drive up US-219, one of the worse cowpaths you can get. Let’s see: I-270 out of Rockville, to I-70 into Breezewood, PA. Your choice of either the PA Turnpike from Breezewood to Somerset, or US-30 thru Jennerstown. At this point, rubes take 30 to 219, but those in the know grab US-220 for about four miles, then PA-56 into Johnstown to catch 219. That’s the hypotenuse of the triangle, and about a 40-50 mile savings.

Up 219 for about four hours to get to Bradford. Well, he could have visited the Zippo plant while he was there.

As to the “why”? In ’66 the Mustang was still hot, and in the DC area it would be extremely fashionable and in demand. Sort of like the first six months for the Smart in that area. Up in the wilds of Bradford (and they are wilds, real civilization is Erie, PA about 100 miles west, or Buffalo, NY about 60 miles north) trucks outsold Mustangs.

As to the route knowledge, guess where I lived most of my life?

Quite a few D.C. residents had weekend or hunting cabins in Pennsylvania, even in the 1960s.

That car was ordered with limited-slip and HD battery, not what you’d expect to need in DC. Maybe the buyer lived up there in PA and gave an MD address for some reason? Cheaper tags? Nice little mystery in that piece of paper.

Custom ordering cars most likely began to decline when option packages replaced individual options around the middle or late 80s.

Options used to cost the manufacturer more than they do now. It’s cheaper to put radios, power steering, power windows, and lots of “luxury” options into all the cars than offer them as options. Now even the cheapest cars have most or all those features, so there’s just not much left to add.

Also I have read that power windows are lighter than manual crank windows

It must depend on the vehicle. I can tell you with certainty that this does not apply to any pre-1978 GM vehicle or 3rd-gen F-body: the first generation power window motors were heavy (but torquier & more robust than their successors).

In fact, since neodymium (rare earth) magnets were developed in the 1980s, and power control electronics have become dirt cheap, our cars are filled with torquey little motors that don’t cost much. That’s why manual window cranks are getting rare. That’s also part of what made hybrid cars practical in the late 1990s.

Neodymium magnets were developed in 1982 by General Motors and Sumitomo Special Metals. GM’s Greatest Hit!

Sorry, I should have said now lighter – obviously it doesn’t apply to older vehicles

Chrysler had a similar system in place. They still had the punchcard for one of my cars on microfiche. I sent away for a copy of the punchcard and decode of what it contained. Unfortunately, the records for Windsor-built Chryslers were destroyed though.

My grandad special ordered his 66 Chrysler with a nonpower antenna in the back, where the optional power antenna would normally be located. To my knowledge, no buildsheet has been found in his car, and my dad’s had most of the interior out before. That would be interesting to see.

A couple more comments on buildsheets in Mopars:

In my convertible, I found a buildsheet inside the back seat. It was between the springs and the seat covering. It was dry, brittle and deformed from being squished in the seat, but I retrieved it almost intact. I pressed it flat, then glued it to a piece of backer board from the craft store and had it laminated. One day I was looking at it and noticed something obviously amiss. I believe it listed a 383-2bbl. while my car had a 4-bbl. which I assumed to be original because it had year-correct carb and linkages. That’s when I compared the VIN and found out the buildsheet actually was for a different car that was almost identical to mine!

When disassembling a parts car, I found the remnants of a buildsheet sandwiched between the frame rail and a bracket for the front bumper. It had been a southern car, but I was still surprised that a recognizable chunk of the buildsheet survived in the elements for so long.

I’ve collected build sheets ever since discovering the one in my first car and it’s still surprising what I find hidden in these vehicles.

Various GM assembly plants such as Van Nuys, Flint, Framingham, Leeds, and Bowling Green typically taped a copy to the top of the gas tank or sandwiched it between the rub strip and tank and surprisingly many survived the environment & remain readable.

I sometimes dismantle old GM cars at the scrapyard just to find these build sheets & it’s probably the most fun part of my car hobby. GM cars are the most interesting as the GMAD plants spelled out each option & also included the name & address of the dealer the car was originally billed to and/or shipped to. Sometimes the car was billed to a different dealer than where it was shipped which is odd. These are the only sheets I know of (other than the IH ones) that don’t require knowing “codes” to read.

Doraville Georgia cars are my favorite treasure trove. I’ve found as many as four buildsheets in the same car before. Doraville sheets can be found under/behind any seat, under the rear package tray, under the carpet, behind quarter trim panels, and on top of the headliner.

Those could have been employee ordered cars for families, I recall that someone could be ordered by one dealer and drop shipped to a family member in another state.

Or fleet vehicles where the company made the purchase at a single dealer and then had them delivered to dealers near the end use location. I know that was the way it was with the company vehicles I had.

Yep, that to, we used to call them “courtesy deliveries”

That’s how it works today where I work. Standard company car is a Mazda6 2.0 GLX wagon. Doesn’t matter where you work, they’re all bought from NZ’s biggest Ford-Mazda dealer, John Andrew in Auckland, and then trucked to the nearest Mazda dealer. Sure annoyed the heck out of my local Mazda dealer that they didn’t get anything out of it (except my loyal support for servicing).

One more great example of Chrysler’s assembly quality of that era. Do you suppose that they mixed up the build sheets? Or did they just ignore the build sheet on several components and use what was on hand? I suppose that someone could have replaced the seat cushion and carried the sheet over from another car. Or someone on the line grabbed the wrong seat cushion (with the build sheet stuffed in it). But your story of a build-sheet for a very similar but different car is a first for me. And I love it. Maybe there is some other guy with another 66 scratching his head over why his 2 bbl car has a build sheet for a 4 bbl.

I’ve seen this happen on GM cars too: sometimes I’d find the sheet for the next car on the line instead of the correct sheet.

One of my neatest finds was from a ’77 Ninety Eight Oldsmobile built in the Linden plant. The copier must have jammed because both sheets found under the seats were printed on both sides — the fronts were correct but the backs were scribbled out & belonged to two completely different vehicles: one was actually a Cadillac.

I think Mercedes in the ’80s was the ultimate ‘have it your way’ company. Not satisfied with punch cards inserted under the seat springs like many US companies did (isn’t that a wonderful find when you’re restoring an old car?), they installed a metal plaque on the radiator support with EVERY option the car has. As Mercedes used some quite unusual specifications, it made it very easy to find out exactly what equipment your car has. Back in the ’80s and up to the mid-90s, Mercedes would allow their customers to choose from a wide array of colours, upholstery, wood, and strange features- and custom built the car from scratch.

Needless to say, this policy meant that if you purchased the car at its listed price, all that was included was the air inside. Living here in the UK, you can see Mercedeii that give a new meaning to the word basic. What’s more, I’ve owned a strange one- ordered almost the way I would- no alloys, ABS, automatic, manual sunroof, manual windows and power locks, no AC but a lovely Becker stereo with Alpine changer in the boot- all on a 300 SE w126- and of course green cloth interior with green paintwork. The only thing I would have done differently is swapped the cloth for MB tex- in green of course. The owner told me that he didn’t trust electric windows, so he specifically avoided them. This was all detailed in a combination of 3 number codes stamped onto the radiator member. He only waited two months for the car, which really for something that cost as much as a house is alot shorter than the time you wait between agreeing a price and exchanging contracts.

Sadly, DB has now gone the way of Chrysler- option ‘packages’ and ‘trim levels.’ The quality has gone, and a 2013 Mercedes is really no different from a 2013 Chrysler 300- although the Chrysler is probably less likely to rust, and the interior is of higher quality than found on many later Mercedes- nearly up to the level of a Fiat.

Interesting!

Didn’t older Mopar trim tags have the complete vehicle option list on them also?

I appreciate the rationalization of options on newer cars. It makes it impossible to order a car with power windows (but not locks) and no passenger-side mirror. Even if I decided I wanted to put new holes in the Imp’s door, I can’t imagine I’d ever find the part.

I do like showing people that it has four cigarette lighters and no cupholders.

The demise of lighters and the rise of cupholders – there must be a correlation there! Gotta have something to put in our mouths when behind the wheel I guess 😉

My grandparents’ Australian-built 1986 XF Ford Fairmont had four cigarette lighters (1 in each door except the driver’s, and 1 in the front console). It really impressed on my cousins and I that smoking must be cool 😉 To this day, both my younger cousin Ed and I each have no fingerprint on one finger due to testing the cigarette lighters while in the back of the Fairmont…! (Gran removed the lighters shortly thereafter as a precaution). No cupholders though!

When my Dad ordered his new Polara in 1972, it took over 2 months to get his car. A strip down 2 door, a month or so after ordering it, he saw his car driven around. A month and a half later, he got the call his car was in. The dealer obviously had sold the first car to another customer, but Dad really didn’t care. He loved the Polara he got, and always said it was the best trouble free car he ever had. The only warranty work done on the car was the drivers window came off the track. He had the car for 15 years when he was rear ended by a young driver. My Dad was taking the car to be serviced.

After being hit, the car didn’t even stall out, and Dad drove it 100 yards to the repair garage. That 72 Polara was a good car.

And if you ordered a Jaguar xj6 in South Africa in 1974 there were NO options, the car came with everything though you could choose the colour of the paint upholstery and carpets. As the cars were made here it was cheaper to spec them to the absolute max rather than add or subtract things.

“They probably had two people punching two cards so the computer could compare them to catch keypunching errors.”

That’s not how it was done. Back in those days, they had a machine called a verifier, similar to a keypunch. Instead of punching holes in the card, it read the card as a keypunch operator keyed in the same strokes. If there was a mistake, the card would be rejected, and re-punched by the original operator and then re-verified.

I did special-order my 1987 Gutless Supreme, as I wanted specific options for trailer-towing. There was no mention of a “trailer towing package”. (Yes, I realized when I bought my next (heavier) boat that I ought to have bought a Caprice instead.) I did order power windows, but not locks. I ordered everything heavy-duty.

There were no “incentives” at the time, (that I was aware of). I negotiated a price, and that was it. I don’t believe I could have gotten a better deal by taking a vehicle from stock.

Thanks Terry, I didn’t know about verifiers. Makes sense.

In fact I just discovered the picture with the two women above actually shows a keypunch and a verifier. Wikipedia (where I got the picture) now says “The woman at the right is seated at an IBM 026 keypunch machine. The woman at left is at an IBM 056 Card Verifier.”

I just revised the text. Thanks again.

“Programmers figured out how to get the computer to do all that production planning, figure out what to order from suppliers, what parts needed to be where at what times. ”

I’m wondering about your assumption of using computers to ordering the raw materials and parts for the cars. I think that’s something of a Japanese technique, required for ‘just-in-time’ manufacturing processes, and really developed in the 1970s and ’80s.

In the 1960s, computers might have been used to do the calculations needed to figure out the ordering required to support a certain production rate, but the ‘planning’ itself, along with the design, was still relegated to actual, human, brainpower and estimating … and then manually checked onthose mechanical adding machines I used to find in the trash piles of Johns Hopkins labs when I was an undergrad.

They might have been able to use the data of actual car orders to project parts installation rates, and then alter original contracts, or speed up delivery of certain items, but I don’t think computer systems in 1966 had the ability to do the complex planning tasks, or provide anything but condensed and sorted reams of data.

Grandparents special ordered a 1969 Electra 225 post sedan with B pillar, and no A/C. But, with cruise control and towing package. Took about 6 weeks?

As far as the possible 1st owner of this 66 Mustang:

My sister bought a 2 year old 67 Mustang, V8/automatic transmission/bench front seat, and NO power options at a VERY small dealership in Dushore, Pa. as a college graduation “present”, before moving to Port Allegheny for her first job. The car’s 1st owner (a congressman) worked in D.C. but his home was in Pa.

The 1st car my father factory ordered was a 60 Ford Country Sedan. We kids pored over the book the dealer gave my father that included paint “swatches” that line drawings of the car you were interested in were placed over. Then there were pages with upholstery fabric “samples” and charts that outlined which body colors were available (by model) and which upholstery colors were able to be ordered with that body color. We wound up getting a blue on blue 6 seat wagon with a 6 cylinder and automatic transmission.

I read somewhere a few years ago in the magazine Ford Times, a magazine dealers used to subscribe customers to, that at least for the Mustang, Ford kept close tabs on which options were popular with buyers, but more importantly which options were unpopular. Sunroofs were never popular with Mustang buyers, and consequently the factory rarely offered them.

BTW, I’ve never understood why Ford offered some interior colors exclusively for convertibles (as one poster here remarked).

I used to work in Dushore. I think that tiny dealership there had built a new facility by then.

Being seriously in the market for a vehicle this year, I’ve been playing with manufacturer build tools and using the internet to search deals, dealer inventory and read window stickers to find what comes closest to what I want.

I’ve found that some cars offer marginal options that are almost impossible to find in dealer inventory. We are talking about things like lighted door sill covers, not anything terribly complicated or expensive, but they are cool. Dealers just don’t order them, I suppose to keep the stickers down or allow space for dealer add-ons.

With all of the digital tools available to the consumer, it sort of fascinates me that the car sales model remains what it is, with the idea of ordering the actual car you want being more difficult than it was 50 years ago, and running the risk of killing all price incentives.

It would seem time for the entire sales model to be revolutionized. Truck mountain, subject to occasional multi-million dollar hail disasters, at the big Ford dealer in my region would no longer be necessary. The dealer could stock a limited number of vehicles for demos and a handful of vehicles for the need it yesterday buyer. Perhaps dealers could be in the loop by providing authorized buyer numbers that customers could use on-line, and the dealer could become the local delivery agent, receiving a flat fee for every car. Meanwhile, the manufacturer could update pricing incentives on a real time basis to accommodate demand and factory utilization. The consumer would benefit as the haggling aspect of car buying would be limited to manufacturers competing across the internet, and buyers could easily get the exact car they want.

Having been involved in customized home sales for several years, it blows my mind that it is harder to customize the $35,000 car that fits in the garage than it is to customize an entire home, lot, and landscaping!

“I’ve found that some cars offer marginal options that are almost impossible to find in dealer inventory.”

Dave, we had this problem when we bought our Kia Sedona. There was a $1500 “Power Package” that added about 4 items, including power side doors. Power side doors were a deal breaker for me, and the salesman said he could get us a van in the color the Mrs. wanted but without the Power Package. That turned out to be a bigger trick than either of us expected. He had to go about 300 miles away to get us one. Which was really funny because the Mrs. had made a big deal up front that she didn’t want a car with a bunch of miles on it. The miles put on in transit (which they didn’t tell us about until I asked) ended up saving us $500 on top of the deal we had already made. 🙂

My ’50 International L-170 still had the LST on top of the glove box…

My ’17 Chevrolet SS has exactly one “Base” trim level, but that pretty much has everything Chevy could throw on it. The only available options were a sunroof, spare tire (standard is an inflator kit) and choice of automatic or manual transmission. I got the roof and a manual.

I’ve only bought brand new twice in my life – both times I special ordered – a 1977 F150 and a 1990 Jeep Cherokee.

My grandfather ordered all of his cars, right up until the last one (which I’m now driving) in 1999. While the last few times it was more likely that he specified what he wanted and the dealer found it in inventory somewhere, he did have a few oddly ordered vehicles over the years. For instance, a ’77 Lebaron coupe with leather interior but no power options, a 1983 New Yor’K’er with the Mark Cross interior option but no rear defroster (in NJ?!?), and a loaded to the hilt 2-tone 1979 Horizon with every conceivable option but no rear wiper (which he cursed about throughout his ownership).

I can recall the discussion when he was trading in his ’94 LHS about whether he wanted the chromed alloys on the 300M (which was one of only a few options available) and whether he’d delete the sunroof for credit. I convinced him to keep the sunroof and forego the chrome wheels. Never imagining that I’d be driving that car 18 years later, if I’d known it though, I’d have suggested the sunroof delete option, as they don’t age well and always end up rattling. I suspect there’d have been a long wait for delivery with the sunroof deletion though, as I’ve never seen one without it.

And then there was the opposite end of the spectrum where everything was done just as they had done it in the 40s. Studebaker typed up a Production Order card that listed the color, trim, power team and options. These were not left with the car. However, anyone with a serial number can order a copy from the Studebaker National Museum.

Sadly, I became very familiar with punch cards when I changed my major from accounting to data processing (as it was called in the day). They destroyed my social life as I was spending my nights and weekends writing programs on them. Back then utility bills were returned with a punch card. A very cool professor of mine alluded that if you took a manual punch and punched a /* in your bill it would take weeks for your check to clear. (If anyone knows what this means you are as old as I am!) I don’t know why he told us this. Perhaps it was because he had a habit on betting on horses.

In many programming languages, /* denotes a comment. Everything that follows, up to a */, is ignored by the computer. This is used to document what the code is supposed to do, for debugging or if you have to modify the code later.

So this would make the reader ignore the card, where just punching random extra holes would make throw an error and someone would look at the card immediately.

Wanted my build sheet badly – couldn’t wait to pull the rear seat on a 69 Mercury. Unfortunately mr mouse had already had his lunch – all that was left was a scrap with (can you believe it) a partial vin – would there be any more hidden on a late 60s model Ford, anywhere?

Now I have three late 60s Fords. The Cougar since Day 1 and I have never seen a sheet and I know I am the only one who has ever looked up the seats and carpet. The Mustang, owned by a woman who many might call the little old lady but wasn’t when she bought it, I never found a sheet during restoration. By the way little old lady owned cars really aren’t in that good of shape many times.

The big 67 Mercury is the same in that I have been throughout the car and found no build sheet. Now the 73 Polara had two copies of the build sheet with one under each seat. Those have been removed and protected.

Dodge build sheet

Well, some things haven’t changed over at Ford. I photographed the underside of my ’13 Boss 302 Mustang a few years ago as a record of how it looked from the factory. There’s dabs of different colored paint on about every suspension part, axle, driveshaft, bracket, line and other bits bolted on or installed. Pretty neat!

More to the point, why can’t you do that today? No reason other than putrid greed. Consider the Chrysler Pacifica minivan, a nice enough people mover with styling cues and front and rear light units suggesting the designers paid careful attention to the 2008 Audi A4, which nevertheless has been pre-hobbled by craven application of the American-market auto industry’s beloved options-bundling scam. Want headlamps better than 1987 halogen technology? No problem! You can get 1994 HID technology, but you can’t just specify them and pay the $500 or so they’d cost as a standalone option with plenty of profit margin built in. No, to get them you’ll have to spend many thousands of dollars to buy a high-spec model which also comes with a whole bunch of extra stuff (and extra-large digits after the dollar sign) you probably don’t want. And that doesn’t get you the HID headlamps, it just makes your car eligible to be equipped with them, but only if you buy the Preferred Technology Group ($9,400; includes smart ashtray, LED footwell lighting with 256 selectable colors, color-keyed rain-sensing rear license plate frame, HID headlamps, power-operated driver and front passenger sunvisors, etc) or the Winter Prep Package II ($9203; includes heated interior door handles, heated sideview mirror adjustment controls, smart spare-socks holder, heated seats for driver and rearmost middle passenger, HID headlamps, heated tailpipe, and coffee cup assistant).

I’ve picked on Chrysler here, but they all do it. Last year Subaru wouldn’t let my mother have HID headlamps on her new Outback unless she bought the uppermost premium model with the 6-cylinder engine. If she’d been in Canada, she could’ve specified them on her 4-cylinder car. These are cars built in the same plant to identical regulations, so we’re talking about an arbitrary decision some greedy MBA made. And it was the other way round with VW when I checked a few years ago: no HID headlamps on Golfs or Jettas in Canada, but you can have ’em all day long in the States (as part of a bloated option package); the bulk wrap official explanation was that VW didn’t want “too many model variants”.

There is absolutely no reason—not cost, not complexity, no reason at all other than pure greed—that the equipment of each and every vehicle coming down the line couldn’t and shouldn’t be specified in line-item detail by the buyer. It’s technically and logistically easier now than ever before. It’s common in Europe. It’s completely doable here, in car plants we’ve already got (such as this one I toured and wrote about). But nope! Why? Because they said so. Pfft.

industry net margins are on the order of 4-8%. it is *entirely* about cost. automakers typically pay suppliers’ entire development and tooling costs, so the more usage you get out of that supplier’s parts, the less of that development and tooling cost is carried by each individual part.

you sound like the typical Internet Car Person. “I expect the car companies to make me my perfect unicorn brown turbodiesel station wagon with a manual transmission, with only the specific options I demand, and it better not cost more than $15,000!”

If you hurt yourself jumping to conclusions like that, the first aid station is about five miles up the hill. Either way, please refrain from putting words in my mouth; it’s really not appropriate on the first date.

I found the punch card for the Mitsubishi Montero I had for a while, I took half the dash apart trying to figure out the wiring issues, and the card was wedged behind the dash. I kept it, cause I thought it was interesting, and now that this article came out, I realize I might not be the only one!

My dad always ordered his vehicles, but usually because he wanted very stripped down cars. He was an Olds guy, and I remember going with him to several different dealers trying to get a downsized wagon with a manual trans. None of the Olds dealers would order one, and we ended up getting a Malibu wagon (a 78) because they were the only ones available with a 4-speed. Man I wish I had been able to keep that, when I was old enough to drive…

the only new car I ever got was a Nissan Versa, I had to go to two different dealers to get a white one with a manual (a 6-speed!) The first place told me, they didn’t offer a manual! I actually showed the sales guy the page in the brochure I was holding, saying “available 6-speed”, and he told me “Oh, that’s not actually available, that was a mistake in printing. You want one with a CVT, anyway…” The other dealer where I lived said they were out there, but they only carried autos and CVT’s. I tried to order one the way I liked, but they ended up finding me one 300+ miles away in Iowa (I was in St Paul MN at the time). They REALLY wanted me to get one off the lot, but those were like 50% more $ because of the options, and I “stuck to my guns” and got the car I really wanted. They did seem to be worried I’d refuse it when it arrived and they’d be stuck with a basic model in white, instead of the loaded-up fancy ones they carried.

Very sad that now a person can’t order a certain option without having to get it in a pakage that includes options that the buyer doesn’t want.

Fascinating article!

I just ordered a Porsche 911, whose options list is INSANE. Numbers haven’t been invented yet that could describe the number of possible combinations.

Things don’t change that much.

No, the last ones I saw were just bigger.. A3 format instead of A4 / letter

I accompanied a school trip to a van factory in Luton in 2005

Making Renault, Nissan Vauxhall and Opel derivatives (Renault designed, GM funded, IIRC). Perhaps they make the FIAT derivative too now. Interesting that the brand was only item no. 4 or so of the build sheet accompanying each vehicle along the line. They had something like 61 seconds to fit whatever needed fitting at each station. Our guide explained that a fully optioned minibus took much longer than that at various stages (optional extra doors, glass, rear glass, rear wipers, seats, carpet, headlining, seatbelts, various electronics) so they spaced them amongst simpler two-door plain vans, which were finished quicker or started later in order to manage. They were very proud of the fact that every vehicle being made was paid for (does that mean the factories themselves sometimes produce ‘stock’ in anticipation of flogging them of to dealers). Also, the engines were not run prior to being fitted (there was no point, they already knew they’d work) – delivered from France perhaps. Oh and there was a big display explaining bonuses for just turning up to work on time consistently. And pictures by the microwaves at the rest stops to show what a clean microwave looks like…

When shopping for my wife’s Lexus ES 350 a few years back the problem I encountered wasn’t the lack of individually available options, but getting a dealer to special order a car. The ES 350 has many individually available options, but cars in inventory contain only two or three sets of selected options. For instance, cars with Navigation also have many other options, while cars without had few other options. Dealers strongly discouraged a special order, stating it could take up to 6 months for delivery and the discount would be far less than on a car in inventory.

Getting lost in the internet age is that first Mustangs were not all “muscle cars” as young car fans think. And why some can’t understand why base models had “such slow motors for a muscle car”. It’s gotten to where “kids” think ALL old RWD 2 doors were “factory muscle”, even Mavericks!

Mustang was a model with may configurations, not solely a “muscle car”. Now, “muscle means money”, so term is thrown around lightly. “want a cheap classic muscle car? Get a Maverick coupe!” seen on a You Tube teenage car kid channel.

Yeah — I think most first-generation Mustangs were ordered with the base 289 and Cruise-O-Matic, which was adequate, but certainly not muscular.

Another example is “Mary Tyler Moore drives a muscle car in her show’s opening credits!”. It was a base model Mustang.

The original JDM Celica allowed a very similar style of cafeteria option ordering, consciously modeled on the original Mustang and presumably executed in a similarly computerized way. You had one body style, but four trim levels, several different engine options, three different transmissions, and an assortment of trim packages and accessories. During the model run, Toyota added some more, filling out certain gaps in the initial lineup. There were thousands of possible combinations, and a major selling point of the Celica in Japan was that you could order just the car you wanted.

It was a vastly different approach than the way Toyota was selling cars here, where we got one or maybe two trim levels (usually from pretty far up the food chain) and there weren’t a lot of extras beyond a radio and whitewall tires.

(There’s a frequently repeated misconception that Japanese cars of the ’60s, ’70s, and even the ’80s just didn’t offer a lot of options, period, which leads to all kinds of specious conclusions, even from automotive journalists and pundits who ought to know better. That was NOT generally how those cars were built and sold in Japan!)

Modern Toyota’s can be “ordered”, but in fact (in the US) all that you’re doing is requesting your dealer to get an allocation for a vehicle that has the specific combination of options that you want. Toyota will build at least a few of every combination, so you’ll probably be able to get one allocated to your dealer and your order, though obviously some configurations are built in huge volume and may already be on the dealer’s lot.