Many of us contributors and commenters lived through the era prior to electronic fuel injection. This meant that most of us have had the “pleasure” of owning and driving cars with carburetors. There have been many comments posted over the years speaking of the misery of operating vehicles equipped with carburetors. To the contrary, the consensus is that EFI is an immense improvement. I wholeheartedly agree that modern electronic fuel injection was one of the most revolutionary systems added to cars in modern times. It allowed engines to run far more efficiently. EFI engines are able to meet ever stricter fuel economy and emission standards without having to sacrifice performance or driveability. In the dark days of mid-1970s to the early-1980s, tuning engines to meet the emission and fuel economy standards with a carburetor often resulted in serious sacrifices to driveability and performance.

Nevertheless, I am a firm believer that a good running carburetor is wonderful thing and it can deliver excellent all round performance, even in modern times. The simplicity of a fully mechanical device that can properly mix the fuel and air to feed an engine and that can be overhauled for less than $100 in few hours does appeal to small segment of people. I am one of those people. Just in case you think my rose colored glasses prescription is a little too strong, let me provided full disclosure. I have a strong penchant for mechanical devices and enjoy tinkering. I have continuously owned a carburetor equipped car for my entire driving history and to this day drive them on a regular basis. In fact, until 2006, I only owned vehicles equipped with carburetors exclusively.

Performing the maintenance on an original factory carburetor isn’t overly difficult. It mostly involves adjustments and the occasion tear-down and overhaul. A factory carburetor was calibrated to operate on a specific engine by some highly skilled engineers and they don’t really need major changes to their calibration or operation. Keep up with the maintenance and they usually will run just fine.

Ford’s Variable Venturi Carburetor was not one of Ford’s better ideas. Owners often replaced these with another carburetor such as Motorcraft 2100 or a Holley 2bbl.

That said, there were lots of carburetors that were not well calibrated and ran poorly even when new. Beginning in the early 1970s, carburetor calibrations were seriously compromised to meet emission standards. Those carburetors from the mid-1970s just before catalytic converters were particularly poor. They were calibrated overly lean and had many driveabilty issues from stalling when cold to poor performance. There were many cars that came equipped with these awful or cantankerous carburetors. There are also some carburetors that have little to no support today. Then there are those owners that modify their engines to improve performance which often requires a more high performance oriented carburetor. The simple solution to all these problems is to replace the carburetor. If the engine in question is a traditional American V8, then there are many new aftermarket carburetors available

The aftermarket offers many throttle body EFI systems that can easily be retrofitted in place of a traditional carburetor. More expensive multi point systems are also available for some applications.

Despite the fact that simple to install throttle body EFI kits are readily available, the number of carburetors available today has seemingly increased. Reading through the carburetor descriptions and using tech support one can usually narrow the choice down based on the displacement, RPM operating range, camshaft, and approximate horsepower. If you believe the ad copy though, you should be able to bolt this new carburetor on your engine and with a quick couple of adjustments be ready to run. The fact is, that carburetor might be in the ball park to run well enough with a few quick adjustments, but it may require a fair amount of time consuming tuning to have good power, driveability and efficiency.

As seen in this diagram, the rich side of stoichiometric ratio doesn’t have a big effect on the engine power, but it drastically increases fuel consumption.

Gasoline and air burn a chemically perfect ratio of 14.7 parts air to 1 part fuel, referred to as the stoichiometric ratio. A carburetor is nothing more than a mechanical device that mixes fuel and air. It is calibrated to do so at a particular ratio of air and fuel depending on the operating conditions. That said, internal combustion engines are very tolerant to burning fuel ratios well outside the stoichiometric ratio, particularly on the rich side with little decrease in performance. This is why one can bolt on an aftermarket carburetor with a generic calibration and the car will run ok, even if not near an optimal tune.

Here is an example of the many versions of the 4MV Quadrajet used by Chevrolet in 1967. Each of these have a unique calibration for each application. Compare this to the aftermarket that makes one carburetor that covers many very different applications.

I overhauled my engine and performed some minor engine upgrades to my Ford Torino. These modifications included increased compression and a more aggressive camshaft. I also upgraded to an aftermarket vacuum secondary 4150 Holley. It fired up and ran okay immediately upon install, but I knew to get my carburetor to run really well, I needed to do some serious tuning. My initial tune was done using traditional methods. I set the carburetor idle settings with a vacuum gauge, adjusted the jetting by reading the spark plugs, and used trial and error to choose the correct vacuum secondary spring. My carburetor was too lean out of the box, and my initial tune richened the carburetor up which significantly increased performance.

The car was running well, but I knew I could do better. I am far from a carburetor expert, but over the years I have developed pretty decent skills at tuning and rebuilding carburetors. Nevertheless, my plug reading skills aren’t up to those of Smokey Yunick. Thankfully today we can use modern technology to help tune a carburetor without Yunick’s skills. An oxygen sensor connected to an Air Fuel Ratio (AFR) gauge will show precise measurement of the carburetors mixture at a particular moment in time. Adding a simple bung to the exhaust allows the use of this tool for a much more precise tune.

Holley carburetors are almost infinitely tunable, but how exactly do you use an AFR gauge to tune one? To understand how to tune one, an explanation of the basics of the Holley’s carbs operation is in order. The carburetor has several circuits, all of which need to be tuned to ensure proper fuel and air delivery.

First is the idle and transition circuit, often simply called the idle circuit. This circuit controls the fuel delivery at idle, but also the transition period before the main circuit starts to pull fuel. While many think that tuning the idle circuit only affects the idle, this is not true. At very small throttle openings the engine is fed by both the idle jet and the transition slot. This circuit is fined tuned with the idle mixture screws, screw in or out to lean or richen. On some Holley’s the idle screws are only on the primary side, but others, have them on the secondary side as well for a total of four idle screws. If the idle screws are unable to properly tune this circuit, this can be adjusted by changing the idle jet size or the idle air bleeds (more on air bleeds later).

The next circuit that comes into play is the main circuit. This consists of the primary jets on the primary side of the carburetor. Adjusting this circuit is simple, larger or smaller jets richen or lean this circuit. An engine’s need for fuel will increase under heavy load situations, resulting in the primary circuit needing further fuel enrichment. This is done by way of the power valve.

The power valve is held close by engine vacuum. As the load increases on the engine and the vacuum drops, the power valve will open. This exposes a second set of jets, called the Power Valve Restriction Channel (PVRC). Much like how a Quadrajet or a Carter AFB will pull a metering rod out of a jet to enrich the main circuit, the power valve opens up to expose the PVRC jets and enrich the main circuit.

The top picture shows that non-replaceable PVRC jets have to be drilled out. The lower picture shows screw-in replaceable jets.

PVRC jets are sometimes replaceable but on lower priced carburetors they must be drilled to increase in size. Like the idle circuit, the main jets also have air bleeds (sometimes replaceable), which can aid in tuning.

The top picture shows screw in replaceable air bleeds while the bottom picture shows non-replaceable pressed in air bleeds.

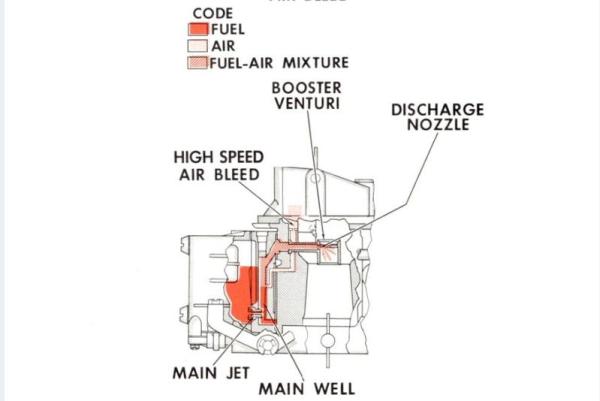

All carburetors have air bleeds or air correction jets which introduce air into the various circuits’ fuel mixture prior to discharge in the venturi. In the simplest terms, air bleeds suck air into a circuit to mix with the fuel. The air bleeds become more effective as engine speed increases, meaning as more fuel is sucked into a circuit, more air in also sucked in. This cancels out the tendency of the mixture to richen up with increased fuel demand. On the main circuit, the air bleeds help tune the fuel curve. If for example the fuel mixture is richening as the engine speed increases, using a larger air bleed will bring more air into the mixture as demand increases and which will lean out the mixture and flatten the fuel curve. Not all Holley’s have replaceable air bleeds, but those that don’t can be tuned by drilling larger or using a small piece of fuse wire to partially restrict air flow.

Four barrel carburetors have a secondary side that only is used under high load and higher RPM situations. The secondary side of a Holley carburetor looks very similar to the primary side, and like the primary side it uses two jets to feed the circuit. The jets and air bleeds can be altered to deliver ideal fuel air mixtures under heavy throttle applications. Unlike the primary side, the secondary side does not have any additional enrichment from a power valve. Since this side of the carburetor is only used under high load situations and not under light cruise or light to moderate acceleration, there is no need to have smaller jetting with an enrichment circuit. The only time this circuit is being used is when maximum performance is needed, so the jetting can be richer. As a result, Holley typically calibrates the secondary jetting to be richer than the primary side because it does not have an enrichment circuit to add additional fuel.

On a vacuum secondary carburetor, the secondary throttle blades for the carburetor are not opened by a mechanical linkage connected to the throttle cable. A small spring loaded vacuum diaphragm opens the secondary throttle plates. The vacuum diaphragm opens the secondary throttle blades based on the engine load, not the throttle input. The vacuum signal from the primary venturi will increase with airflow. After a certain point, it will allow vacuum into the diaphragm. This vacuum will eventually overcome the spring pressure and allow the secondaries to open. Tuning of the rate of opening in crucial to optimal performance and is done so by way of changing the internal spring. A too soft spring will allow the secondaries to open too quickly causing a bog. A spring too stiff can cause them to open too late which compromises performance.

Finally the last area of tune is the accelerator pump circuit. Sudden opening of the throttle on a carbureted engine, in particular those with high vacuum, results in the fuel falling out of atomization. To overcome this, the accelerator pump shoots extra fuel into the carburetor to help compensate for this fuel loss. This shot of fuel needs to be appropriate to ensure the engine doesn’t go too lean or too rich. Holley has several areas that can be adjusted to get the pump tuned correctly. The squirter size can be increase or decreased. A smaller squirter will shoot a smaller fuel shot but do so over a longer period, while larger squirters will shoot more fuel over a shorter duration. The pump is activated by a cam, and Holley offers numerous cams that alter the accelerator pump curve (see chart above).

This is the O2 sensor I installed which allowed me to use my AFR gauge. It can be removed and plugged when I am done tuning.

On my particular carburetor, I went through and re-tuned all these circuits with the AFR gauge. The AFR gauge clearly showed if a circuit is running too rich, too lean or at an ideal mixture. Using my old school methods of tuning increased the engine performance and my fuel consumption. I discovered that I went too rich for most of my adjustments, which meant I could make significant efficiency improvements. I used my AFR gauge with trial and error under various driving to help adjust each of the above circuits. I was able to get my Holley to run at a much leaner, cleaner and more fuel-efficient cruise, and had no loss in performance. Even my wife commented that the exhaust smell had dramatically improved.

I temporarily mounted the AFR gauge in my ashtray so I could read it as I drove. I powered my gauge through the cigarette lighter. This allows for easy removal once the tuning is completed.

A carburetor will always be a compromise over a EFI system, but with and AFR gauge and some proper tuning you can have a pretty well-mannered machine that operates very well. Finding a mechanic that can tune carbs today is about as rare as hen’s teeth. Nevertheless, most mechanically inclined hobbyists can use this modern technology to drastically improve their classic car’s carburetor operation.

Great article and in-depth analysis from your experience. We’ve all been spoiled with the reliability of EFI. I only have one carb car left, it uses a staged 2 bbl on the Chrysler 2.2L. The idle mixture screw, courtesy of the masochistic engineer who designed the installation, is located opposite the valve cover. This often necessitates removal of the carb to properly adjust it. Can be done on the car, but I’ve lost numerous allen wrenches doing it.

Thanks for the tip about the AFR gauge. I will have to pursue that further.

One word… Quadrajet. The ultimate carb for a daily driver, if you understand how they work.

Q-Jets are great carburetors, probably my favourite of all for a daily driver. I have a freshly built one for my old Chev. The E4MC Q-Jet, on the other hand, is not my favourite. I have owned these as well and overhauled them, and they are a compromised design IMO.

This is great, Vince. Another important thing to remember when using a wideband O2 sensor is that it’s reading an average from all cylinders on that bank. Therefore, checking out the plugs for “outliers” is still a useful tuning tool, because individual cylinders can still be rich or lean, even when the AFR reads that it’s in a good range. I’ve also found that it’s important not to shoot for a specific number on the gauge, but to let the car tell you what’s right. My Firebird and Dart cruise well at 15:1, but my Corvair and Mustang prefer something in the low to mid 14:1 range.

Additionally, modern AFR meters are tuned to identify the stoichiometric radio as “lambda,” but that will read 14.7 on the gauge (according to a call I made to Innovate, the manufacturer of my system). Some will say that you have to set the mixture richer when running E10, but the gauge will always read 14.7:1 at lambda, no matter what the percentage of Ethanol is in the tank. Take that with a grain of salt…I didn’t program the equipment; I only talked to the company who made it. 🙂

Thanks Aaron. Yes, absolutely the O2 sensor is only getting an average of the cylinders, and typically on one cylinder bank. My engine seems to be relatively equal for fuel air mixture, but inline engines with long manifolds and one carburetor would definitely be more susceptible to significant differences between cylinders. I agree you have can’t live and die by the numbers and have to tune what the engines needs. My engine has a very strong ignition system that allows for lighting off lean mixtures without misfires. In my case, my engine had no issues firing even leaner mixtures, like 16:1 or higher. However, the responsiveness was definitely affected if I went too lean. It’s a lot of trial an error, but certainly an improvement over the old school tuning methods of carb tuning.

I used an AEM gauge, but would think the effect of ethanol would be the same as your innovate. However, I am lucky that there is quite a few ethanol free gasoline sources in my area, although only in the more expensive premium. All of my old cars get ethanol free gas. That said, a carburetor can run fine on ethanol if properly retrofitted, contrary to some of the comments her (not yours).

I had a 1972 Ford Maverick with a 250 c.i. straight six and a 1 barrel Carter carburetor, and plug #’s 3 & 4 always ran rich, with heavy deposits on the electrodes, while plug #’s 1,2, 5 and 6 always ran leaner. Plug #’s 1 and 6 were the leanest, because they were the furthest from the carburetor, while plug #’s 3 and 4 were the richest, directly under the carburetor. This was likely the result of mixture separation in the manifold, a problem even throttle-body fuel injection won’t solve. Only port fuel injection and direct injection can ensure that each cylinder gets the correct mixture all of the time.

Yes you need a richer mixture with E10 and yes since the O2 sensor’s output is Lambda it tells you if it is operating at stoichiometric, rich or lean. It has no clue what the A/F ratio was that obtained that reading since it measures the O2 in the exhaust as the name implies. Gauges that are sold at AFR meters convert that Lambda output to a pure gas A/F ratio. So yes you can use it to tune a car for E10 or even E85, but you are still shooting for that 14.7 reading.

Definition of a carburetor:

A precision device doing an approximate job.

Back in the day, I used to rebuild Ford VV 2700 and 7200s for several Ford dealers and a couple of independents. Set up right, they worked well but had some inherent flaws that made them less than durable. Good idea, poor execution.

That definition! »chef’s kiss«

I am kind of fascinated by the VV carb. I’ve never had any contact with them, and likely never will, but I’d love to read about them in detail.

Just a reminder that using any ethanol blend fuel in any carburetor usually wipes it out. This happens usually for infrequent use vehicles, after only 30 days, phase separation occurs and formic acid results, ruining most carburetor gaskets, the rubber parts, O rings in Holleys. My big wrecker Ford 390 with Holley 4 brl would sit for a few weeks after being on the open road where pure gas wasn’t available. Carburetor had to be rebuilt several times. After the last overhaul, I made sure that I only put pure gas in, and now it can sit for months, and runs perfect each time. It’s a hassle to go 30 miles to fill several 5 gallon containers with pure gas, but well worth it. I’ve also found that the ethanol blend corrodes the viton needles, so you’re better off with all metal or the two balls N and S assembly.

I replaced my VV with a Motorcraft 2150.

Great stuff Vince, even though the only carbureted engines I have anymore are for cutting grass, not driving.

But I’m old enough to remember the trial and error methods of adjustment on my ’73 LTD (which most likely had that 2BBL that you mention wasn’t very good), and my ’79 Futura with it’s tiny little 1BBL that I could take apart and put back together in my sleep.

I think that the ’83 T-Bird had a 2BBL carb, but by then it was controlled electronically.

I’m curious as to the kind of gas mileage you are pulling down with that 400 in your Torino. Since you have a ’72, your performance was not as compromised by pollution controls as my ’73 LTD and it 351-W. I also had a considerable weight disadvantage going on with my car. High single digits was the norm in the city… maybe 10 MPG tops, but I could get about 15 MPG with the old girl on the highway if I took it easy. These were also in those lame 55 MPH days as well, so I’m sure that didn’t help, as in my more recent experience, cars get much better gas mileage at 65-70 than they do at 55. Of course that could be modern tuning at play here.

Thank you Rick. Dad used to keep detailed records on the Torino including fuel economy records. It typically averaged about 18 mpg in mixed driving, favouring more highway than urban. The car was mostly used for longer distances, but if just used for short trips in town it could go as low as 10 or 11 mpg. His all time high was 21 MPG when traveling across Canada.

Since I have overhauled the engine, I have calculated the mileage once at 15 mpg. This was prior with this tuning. Dad always asks me what the mileage is like, and I tell him “I don’t care.” While a track our daily driver’s gas mileage in a spread sheet, I don’t with my old cars. Quite honestly it takes the fun out of it if I am worried about fuel economy. Plus, I tend to like to drive the Torino somewhat aggressively when the opportunity presents itself (all with appropriate safety precautions of course). The engine pulls so strongly now that it is somewhat intoxicating and it is fun to drive fast on curvy backroad highways. In any case, maybe the next long trip I will calculate the mileage just to see where it’s at.

Now that my Mustang has been retired from daily driver duties, I don’t keep track of the gas mileage on that car either.

I do get curious though if my wife and I use it for a trip, but since my direct injected 1.5L turbocharged I-4 in my Honda Civic absolutely kills it in the gas mileage department (39.6 on a recent mountainous cruise to WV and back), the Mustang doesn’t do many trips anymore.

It’s just the pleasure driving that you cite here for the old girl. And like you, I don’t care. I mean, how much gas am I going to use driving to cars and coffee, or just taking a drive in the country? 😉

I’ve never touched the one barrel carb on my ’66 F100 in 35 years. The plugs always look a very happy light tan. If it ain’t broke…

I am not surprised, you shouldn’t have to do much to it. I think the fact you regularly use it but it doesn’t see a lot of mileage plays a big role in the lack of required maintenance. I said this in the article:

“Performing the maintenance on an original factory carburetor isn’t overly difficult. It mostly involves adjustments and the occasion tear-down and overhaul. A factory carburetor was calibrated to operate on a specific engine by some highly skilled engineers and they don’t really need major changes to their calibration or operation. Keep up with the maintenance and they usually will run just fine.”

I can say all of the cars I have owned over the years that ran good factory carburetors, this Torino included, have required very little maintenance as well. I was aiming this article at tuning a new generic aftermarket Holley.

I may have created the wrong impression. My point is I’m glad it hasn’t needed anything, as I don’t feel competent with carbs, and this fine article only reinforced that point.

It’s all good Paul. 🙂 I was just reinforcing your point that most stock carbs, at least the good ones, don’t need much maintenance and should not need any significant calibration.

If you’re getting “tan” plugs with unleaded gasoline, either the plugs have thousands of miles, or the mixture is pig-rich.

Unleaded gasoline may produce some hint of color–orange, maybe, or green–on the porcelain from certain additives in the fuel; but in general folks would say the porcelain is “white”. Lots of folks think this means the engine is running lean. But unleaded gas just doesn’t color plugs like leaded gasoline did. It takes a pile of miles to put “tan” on the plugs.

They’ve been in there for several decades. I see no apparent reason to replace them.

Several decades??? Good thing they get pulled out now-and-then, so they don’t seize in place. If the center electrode is getting rounded, they’re done. If the center electrode is still nice ‘n’ flat on the end, I suspect the plugs are fine.

But that does answer the question about whether the “tan” is normal or not. 🙂

I think you are greatly overstating the case. Spark plugs don’t look the same for any given quality of combustion with unleaded as they did with leaded, but spark plugs remain readable. They’ll stay squeaky-clean a long time in a modern fuel-injected engine, but who needs to read the plugs in one of those? A carbureted engine—or even one with a less-sophisticated fuel injection system—will rather quickly colour the spark plugs even if they are of exactly the right heat range and the fuel-air mixture is ideal. Tannish, varying with fuel formulation so it could be greyish or pinkish, etc, is still the target colour. Black and dry means cold and/or rich; black and crusty still means rich; black and wet/gummy still means oil, bright white with/without crust still means lean and/or hot.

Your idea does surely apply to the obsolete art of reading tailpipes, though, to evaulate combustion. That did go away with leaded gasoline, which used to put a beige coating on the inside of the tailpipe when all was ideal. With unleaded, even as-close-as-possible-to-perfect combustion (even lean combustion!) will still turn the tailpipe black.

i get it , and appreciate the skill and knowledge involved. But i dont miss them. Other than my galaxie and my fairlane,Every car I have owned or assigned have been FI. Have had 2 FI issues in 40 years. Saab 99 running on 3 cylinder. Pulled injector and found a TINY piece of something or other jamming the tip of the injector, removed. And my 87 golf had a brief cold start issue that was ( i think) a pressure regulator. Thats it. Below zero starts? yes. In fact had a memorable one when my 2012 Charger v6 was out in -20 for a whole day while skiing in N VT. When I hit the started it did NOT sound good, the battery was obviously affected and cranked at waht felt like 40% or less speed. But the engine fired off, and after giving it a few minutes, we drove off.

Great article Vince! You have convinced me that an AFR guage and sensor is the way to go when my Ghia motor gets its higher compression heads and new Weber carb. The extra cost vs. the risk of damaging the motor by running too lean is not worth it and just reducing time and guesswork will be a boon.

Love your articles on the practicalities of owning old cars – keep ’em coming!

I have been extremely fortunate in never really having a significant carb problem in any car I have ever owned. Except for the 77 New Yorker, but that Lean Burn Carter Thermoquad was poorly set up from the factory.

My only experience in rebuilding came with my friend Lowell in high school when he wanted to rebuild the 2 bbl on his Cougar’s 289. We thought we followed the directions but we couldn’t get it adjusted so that the car would run well. He finally gave up and took it somewhere. It really stung when the guy at the shop said “If you can rebuild it, you ought to be able to adjust it.” He was right, of course, but we knew close to zero about carbs then.

This was really interesting reading!

WELL DONE!

A few things I want to amplify:

1. Most folks put bigger jets in a Holley if it’s lean when the throttle is WFO. This is a mistake. The main jets are intended to provide a properly-lean CRUISE mixture. Under heavy throttle, the power valve channel restrictions need to be opened-up or made adjustable as you’ve shown. Adjusting the power circuit (difficult) instead of the cruise circuit jets (easy) reaps benefits in reduced emissions and improved fuel economy.

2. There’s a big deal in Holley circles about “Four Corner Idle”, where the idle circuit on the secondary side is adjustable just like the primary side. This gives the impression that the regular carburetors don’t have an idle circuit on the secondary side. Of course they do–but it’s not adjustable. The idle circuit is designed and machined so that it’s appropriate for the majority of engines that particular carb would be used on; all the adjustment needed for a specific engine is done on the primary side. A secondary idle circuit is needed to keep the fuel in the float bowls fresh; the idle circuit doesn’t flow much fuel, but it does flow enough so that the float bowl gets replenished with fresh fuel whenever the engine runs.

3. Holley carbs have been manufactured in so many variations that it is vitally important to use the correct replacement parts. An incorrect gasket with a certain hole in the wrong place, or a casting that’s been machined a bit differently, can totally ruin the ability of the carb to mix fuel and air in the proper ratios.

4. A properly-functioning choke makes a huge difference in driveability, engine life, oil contamination, emissions, and frustration level. I’ve never seen an aftermarket Holley that had the choke adjusted properly from the factory. Guys will drive themselves to the brink of madness, turning the choke coil richer/leaner/richer/leaner in a never-ending quest to get the choke to close appropriately so the engine runs right when started, and shortly thereafter. This is crazy. DO NOT adjust the choke so that it closes like you think it should. Adjust the choke so that it OPENS correctly, with the speed of opening timed to the warm-up characteristics of the engine. In general, chokes get adjusted “too lean”, they open too quickly, and the engine runs crappy until it warms up because the person doing the tuning has totally overlooked the choke pulloff mechanism adjustment. Or the choke pulloff diaphragm(s) have ripped and the pulloff doesn’t work any more.

The choke pulloff piston adjustment of many Holley aftermarket carburetors is sealed behind a blort of caulking; most folks don’t know that the adjustment screw even exists. If you buy an “electric choke conversion kit” from Holley, there’s zero mention of this screw or how/why to adjust it. And yet, that adjustment is CRUCIAL to proper choke function.

If an engine is in otherwise good mechanical condition, has a choke that is adjusted properly, and running seasonally-blended fuel, appropriate oil viscosity, heated air intake and exhaust-warmed intake manifold, with a powerful battery, a carbureted engine will start and run SEAMLESSLY from -20F to full operating temperature, including engines with mild-to-moderate aftermarket camshafts. The emissions profile and fuel economy may be worse than a similar fuel-injected vehicle; but not the driveability.

As the Wise Man said, “Every carburetor ever built functions on the principle of “Suck and Hope.””

A high-school kid can overhaul and adjust a carburetor to stock specs. The high-school I attended had an Engine Mechanics course; Dinosaurs roamed the Earth, and every student was required to overhaul six carburetors and perform six “tune-ups”; this did not have to be on the same vehicle. No parts were supplied by the school, this had to be paid for independently. Can you imagine twenty students in each of two classes, all needing to find enough suckers to not only volunteer their vehicles, but cough up for the needed supplies–carb kits, floats, spark plugs, maybe a plug wire or two, fuel and air filters, distributor cap and rotor, etc.? And yet, every student accomplished these tasks by asking friends and family, working on the student’s own car, etc. Today, “parent(s)” don’t even need to feed their kids let alone buy them car parts. The difficulty with carb overhauls comes when the fuel curve needs to be altered from stock specs. In other words, it’s the tuning of the carb that’s difficult, not the disassembly, cleaning and inspection, and reassembly.

Thank you and thanks for sharing your knowledge. I didn’t mention it but I did have to work on the choke too. Once I leaned out the idle with the AFR gauge I had to adjust the pull off on my Holley, The new leaner idle too lean when cold and was stalling until I richened the choke. Once it was richened up, it worked fine. I agree, few people seem to know how to do this adjustment.

As the owner of two motorcycles sold with carbs well into the fuel-injection era, and the emissions regulations that drove most manufacturers to adopt FI, I hate the carbs. Between shoddy aftermarket jets and needles (CV carbs) needed to correct mixture to give adequate drivability, and sensitivity to fuel quality, I’d much rather have FI. On the other hand back in the seventies and eighties when I did have carbureted four wheeled vehicles, they did run just fine. One minor correction though: you wrote “Even my wife commented that the exhaust smell had dramatically improved.” I think you meant “my wife immediately commented that the exhaust didn’t stink any more, and even my gearhead friends who grew up in auto shop and at the drag strip noted the cleaner exhaust.”

I agree, getting quality parts for carbs is difficult today, particularly stock rebuild kits. At least with well supported carbs like Holley, you can get somewhat decent quality parts. And I like your edit, it’s not far from the truth.

Great job on the article. And we won’t even discuss the fuel curve for a marine engine.

Growing up in the early “smog control” era of the 1970’s, even factory carbs were abysmal. When American car makers finally bit the bullet in the mid 1980’s and began to install factory fuel injection, I was overjoyed! Finally, Detroit was catching up to the Europeans! I knew that Detroit had fallen behind when you could get Bosch K-Jetronic EFI on a VW Super Beetle in 1976! Then the “hot rod” car magazines began writing about future fuel injection retrofit kits for Detroit iron. The early kits were horrendously expensive, difficult to install, and almost impossible to tune without access to a chassis dyno, requiring professional installation that just added to the cost. The kits were aimed mostly at racers who would pay almost anything for extra speed. It took about twenty (20) years, but like everything electronic, the cost went way down, the systems became much easier to install and tune, and were made for more and more engine models. Today, there’s no reason to hang onto carburator technology. If you want to be constantly fiddling with a carburetor with every change in temperature and humidity, fine, but me, I’d rather be driving! Go EFI!

Outstanding article Vince, and another reason I appreciate the Curbside Collective. I left carb tuning a few decades ago but appreciate the art and diligence required to do it right. Great mix of detail without getting too bogged down.

Carbs were always a problem here in the Rocky Mountains, as a set air/fuel ratio is never correct with major altitude changes. What’s right at 5,000 feet is totally wrong at 11,000, and the engine and exhaust tell you that. Carbs work great in the relative flatlands, but EFI shines in the mountains.

Well Said. Those of us here in the “flatlands” don’t see the large altitude changes that you drive through routinely in the Rockies or Alaska. Here in New England, altitude variations rarely exceed 3000 feet above sea level, and the highest peak east of the Mississippi River is Mount Washington, at 6288 feet above sea level. Combine the large altitude changes with the temperature and humidity changes with altitude that are common in the Rockies, and I wonder how you could keep a car tuned at all!

I deal with 5 cars that have carburetors all of which are Autolite right now. All were originally sent out 18-25 years ago to Jon at Pony Carb where he rebuilds and makes improvements on the factory design and those days are over. While the 2100 and 4100 tend to generally run Ok, before modification, his work on the 4300 was magical. He would run them on an engine before returning. The Cougar currently has a 4100 1.08 but has a 1974 Holley backup that was worked on by Fuel Curve Engineering back in 1976 and was used for 20 years before blowing the power valve. That was fun. I recall it got 17 miles per gallon vs. the 12-13 mpg the original 4300 got. Fortunately all I have to do nowadays is a basic rebuild given the the internal mods are fixed in place.

Excellent post, by the way.

Thanks all for the comments. My intention wasn’t of this article wasn’t to say that carbs are better than EFI, because they aren’t. That doesn’t meant that carbs are all awful and a pain to live with. They don’t require constant maintenance or cause lots trouble, but installing a new carb does require some calibration. Tuning carburetors is a dying art and I hope that maybe some of the old car owners out there might be encouraged to take a stab at learning how to tune their carb.

I must admit I was thoroughly enthralled reading right up to the spark plug chart. Then came all the adjustment screws, settings and explanations. Suddenly I had a flashback to all the accompanying vacuum lines from the 80s cars I grew up with. The epitome of which was my Stepdad’s untamable 83 Jaguar V12 XJS, aka Medusa. In my mind carburetor tuning is as nuanced as a tourbillon watch movement and maybe more so. Few things automotive are more beautiful than twelve velocity stacks on a classic Ferrari though. The ability to finesse a carburetor is the mark of a true connoisseur. That said I can’t put into words how much easier life became when I purchased my first fuel injected car. Not only did it start but also ran just as good at 40 degrees below zero as at 72. But even as great as fuel injection was I look forward even more to the day when my car runs on electrons. That said it only increases my appreciation for the mechanical analog experience of a carbureted engine.

I worked on lots of carbs over the years, especially during my years at the GMC dealership. Holley’s were always pretty straight up for rebuilding and repairs. The worst Holley’s were the final years they were used on the 366 and 427 medium duty engines. They had lots of drivability issues. It was so bad that GM developed a kit to fix the issues. I installed many of the kits and it did correct the problems, it was an easy install unless it was a school bus. Part of the kit was putting an electric fuel pump in the tank. The fuel tanks are a supreme pain to remove from most school bus’. I did a short cut that got the pump in and made servicing the pump very easy.

Quadrajet carbs were another story, it was a good carb but they there own special problems. Fuel bowls that leaked directly into the engine. Crappy design accel pump.

The worst was when you got one in for drivability or starting problems and you discover that it had some generic parts store rebuilt carb on it. Time to go get the BIG Rochester Carb spec book and start checking all the settings and making the adjustments by bending the rods and checking choke plate angles. That would usually fix the problems if the rebuilder hadn’t totally buggered up the throttle plates or the main castings.

Still have my Rochester book for that occasional Chevelle that’s still sporting the Quadrajet.

My last vehicle with a carb is a lawn mower, and I’m good with that. I did have the problem that my real coming of age, automotive wise, mostly related to ~1970 cars. A bunch of them. So I’m biased. Making them run well alone was a feat, although I found of I hogged out the accelerator pump jet I could eliminate or at least minimize the eternal flat spot. But making them run well and pass smog. OMG!!! An impossible task. I did find if I leaned out the idle screw, constantly increasing the butterfly opening until it was mostly running at idle, on the main jet, I could pass smog pretty well. Didn’t drive worth a damn though.

My fuel system rubber problems were exclusive to a Toyota Celica I had, ’75 IIRC, which was a rare bird for that in that it had great drivability and passed smog. But until I replaced every bit of rubber in the fuel system, including in the carb and the little known “auxiliary accelerator pump diaphragm” I still had lots of problems.

Holley experience is limited to two. A friend with a mid 60’s Corvette, yes, that one, with a 327, but back when it was affordable in the mid 70’s. It had probably been tweaked as it was 10 years old at the time, but it either smoked at idle and fouled plugs, or was crazy lean at speed. And my Jeep pickup truck, with a very different 327, the Rambler one, with a 2 barrel, stock. Totally gutless, but with a flat spot as wide as Kansas. Putting on a Ford, yes, labeled Ford, not Autolite or Motorcraft or anything else, putting on a Ford Carb made it run so much better. Mostly torque and drivability, not so much HP.

And my early 70’s BMWs, with even more vile Zenith carbs. After several rebuilds, soaking them in carb cleaner etc, I got to the point where I could pull the top of the carb off, pull a couple of jets out, spray the passages with Carb Cleaner and be on my way in 15 minutes. I don’t know how often I did it, but more often than the 4K oil changes at the time. Still idled like crap, but it would idle again.

They were crude devices, worked ok when emissions and economy wasn’t an issue, but so far as I’m concerned a relic best left to the early 1960s at best. I can work on them, I have, it’s a wonder I don’t have cancer from my hands in that yellow carb cleaner that would eat the cans they came in within a year or so, but I have no love lost for the devices.

What I miss from the era is the good carb cleaner in a bucket that actually works.

The stuff that would take off a layer of your skin (when not wearing gloves) and clear your sinuses in a heartbeat.

This feels like a trip down the rabbit hole since my experience is with slide type motorcycle carburetors which don’t have any complex valves and circuits since the slide varies the venturi size and the tapered needle adjust fuel flow. I guess the closest car equivalent is an SU or Stromberg since they work like motorcycle CV carbs.

Then again I’ve had precisely one car with a carburetor since 1986, everything else was fuel injected.