The Honda Accord quickly became the benchmark modern car in the 1970’s – 80’s with its superb fit and finish, good handling, and fuel efficiency. The Honda Accord gained a stellar reputation in that era and, consequently, sales steadily increased over this time. Not surprisingly Honda’s competition noticed the early generations and refined their own designs. However, their efforts still weren’t enough to dethrone the 4th generation U.S. Accords during the first couple years of production, during which time the 4th generation Accords outsold all other cars in the U.S. However, by the 4th generation’s last year in 1993 sales dropped precipitously by over 60,000 units and the Ford Taurus moved into the number one slot.

The 4th generation has often been cited as the “peak” Honda Accord. However, one major weakness of this generation was that, like many Honda products of the time, its creation was driven by engineering wants and needs rather than customer wants and needs. While the engineering focus made for an excellent automobile, Honda lost money designing the conservative 4th generation Accord. In fact, the 4th generation Accord cost Honda 10% over budget. Furthermore, at this time, a 5-cylinder derivative pushed by R&D of Japan to bolster Honda’s sportier image failed to succeed. To make matters worse, the Japanese Bubble Economy, which had allowed this engineering excess to occur, was coming to an end. The company whose innovative engineering had led to their good fortune was heading off course. Something had to change.

In 1990, Nobuhiko Kawamoto had become CEO of Honda. His leadership brought a new era to Honda. Mr. Kawamoto was a Honda engineering veteran. He worked alongside Soichiro Honda himself and also helped develop Honda’s revolutionary Compound Vortex Controlled Combustion engine. While at the helm, Mr. Kawamoto had to make some very difficult decisions in order to ensure Honda’s future. He ended Honda’s legendary involvement in Formula 1 racing, citing cost reductions. Most significantly, however, while he realized the importance of engineering to Honda, he saw that the current engineering dominance was not aligned with consumer tastes. He observed engineers designing and building vehicles to please themselves, which then were not selling well, nor turning an adequate profit. He did what no CEO before him would have dared do and went directly to Soichiro himself, telling him change was needed. Soichiro gave his approval, and regrettably died only months later.

Mr. Kawamoto started a course of change by abolishing systems set-up by Soichiro and embarking on new consumer relevant projects like a minivan and sport utility vehicle. Mr. Kawamoto also realized that the next Accord, upon which Honda’s future hinged, would need to be an agreement between both engineering and financial officers, so that costs did not spiral beyond control as with the 4th generation car. Honda’s continuation was riding on the new 5th generation Accord. It was an essential product for Honda. Mr. Kawamoto was quoted as saying, “If this [5th generation] car fails, we [Honda] won’t survive.”

The design of the 5th generation Accord had a rough start in September of 1989, just after the 4th generation cars debuted. Designers and engineers were asked, in their design phase, to consider how to avoid potential assembly line start-up issues, similar to those that had plagued the 4th generation production. Furthermore, the 5th generation Accord objectives were very challenging, and included cutting new equipment investments in half, carrying over 50% of the parts from the 4th generation, and holding the total spending level equal to that of the 4th generation, thereby anchoring the price.

To help keep production costs reasonable, 5th generation engines were largely a carryover from the 4th generation aluminum units. This was not a bad decision, as the previous units were well up to the task of being remarkably reliable, rev-happy units perfectly befitting Honda’s sporty reputation. Improvements included a slight power increase, and all engines worldwide included Honda’s PGM-FI fuel injection system for the first time. Another first in Accord history was the arrival of VTEC, a variable valve timing technology, on some Accord variants that improved power and fuel efficiency further while minimizing the environmental impact.

Engine displacement varied between 1.8-2.2 liters, with mostly single overhead cam configurations offered. The small 1.8 and 2.0 liter sizes were only available in certain countries, like Japan, and were offered mainly for lower taxation purposes where vehicles are taxed based on the size of engine displacement. However, higher power options were also available for the Japanese market, including a 2.2-Liter SOHC VTEC and an even more powerful 2.2-Liter DOHC VTEC. The 2.2-Liter DOHC VTEC engine was similar to the then current Honda Prelude 2.2-Liter engine. It used metal matrix composite cylinder liners composed of an aluminum and carbon fiber mixture to reduce engine weight and size, but gain higher horsepower with respectable fuel economy.

Initial engine choices for North Americans were considerably sparser, with only a 2.2-Liter non-VTEC SOHC and an almost identical Japanese version 2.2-Liter SOHC VTEC offered. However, some at Honda later felt that Americans needed a V6 engine to stay competitive with rivals. A new 2.7- Liter SOHC V6 was introduced for 1995. The 2.7-Liter V6 was similar to the Legend V6 already in production at Honda’s Japanese Wako engine factory and required only an extra $2 million in tooling costs to produce, as opposed to a $50 million investment had the engine been slated for a new line at Ohio’s Anna engine plant. The V6’s larger displacement required an engine bay stretch, which necessitated new front fenders, front bumper, grill, and hood. Honda did not introduce the V6 earlier because of their limited resources and the decrease in fuel efficiency. This optional V6 Accord was never offered in Japan.

5th generation transmission choices were largely a carryover from the previous 4th generation. A 5- speed manual or 4 speed automatic were available, with automatics being overwhelmingly more popular. Automatic-equipped vehicles utilized one of Honda’s last revisions of its 4-speed H4 transmission family with lockup torque converter termed the H4A. On vehicles with a 2.2-Liter engine or larger, the H4A introduced a new technology termed “Grade Logic Control” in the U.S., or “Progressive Shift Schedule Management Technology (Prosmatec)” in Japan. This new technology calculated expected versus actual acceleration to “sense” if the vehicle was climbing a hill, resulting in the car automatically dropping down to a lower gear to help maintain revs and minimize “gear hunting”. It also worked as an engine brake going downhill and would automatically drop down to a lower gear to slow the car down based on vehicle speed and operator pedal input. This technology was exclusive to automatic transmission vehicles.

Notably, the H4A transmissions proved to be one of Honda’s last heavy-duty automatic transmissions. Compare the difference in failure rates between these units and the medium-duty 6th generation automatic units, especially the V6 variant, and the results are startling. The H4A is clearly a more rugged transmission. The H4A however can be noted for hard shifting, especially as the vehicle ages. This was why Honda addressed this criticism with the 6th generation Accord which shifts smoother at high mileage, but at the expense of long-term durability.

Suspension is a key component to a good handling vehicle. Here, the 4th generation’s over-engineering became a saving grace for the 5th generation where cost accountants dictated reuse and refinement of 4th generation parts to lower costs. The 4th generation suspension parts were tried and true tested components. The Accord’s 4-wheel double-wishbone suspension arrangement had been based on Honda’s previous involvement in Formula 1 racing. It was a fairly unusual setup for a family vehicle and was not cheap to design or manufacture.

Achieving a balance between crisp handling and a comfortable ride, was a top priority. Being an imperative expectation for the 5th generation, Honda refined the double wishbone suspension design for more wheel travel, allowing the vehicle to soak up bumps and imperfections in the road with ease, while famed Japanese racing driver Motoharu Kurosawa, one of Nissan’s ex-top factory drivers, reportedly helped tune the suspension. As development neared the end, engineers realized they had leaned too far towards comfort and scrambled to fine tune the suspension further. Even Honda’s CEO Nobuhiko Kawamoto became involved and secretly stole through the streets of Los Angles in a prototype under the cover of darkness to ensure the new Accord handled just right. This intimate attention to detail ensured the suspension did not disappoint. Add in a standard front sway bar, speed-sensitive rotary rack and pinon steering, and a hub over rotor front disc brake design to reduce un-sprung weight, and the handling of the 5th generation gave an exceptionally high feeling of confidence. This attention to suspension detail continued throughout the Accord line with higher horsepower versions also receiving a rear anti-sway bar or thicker sway bars, based on the market, for additional sure-footed stability.

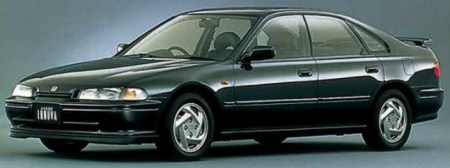

Honda chose one new platform for the 5th generation in North America and Japan, christened “CD” for sedans and coupes and “CE” for wagons and V6 models. Europe received the old restyled 4th generation “CB” Accord platform sold concurrently in Japan as the Ascot Innova. Notably, the new 5th generation platform width was approximately 2-3 inches more than its “CB” predecessor. This key decision created a problem in Japan. The new “CD” and “CE” platform did not fit within the favorable compact car segment anymore, making buyers liable for more automobile taxes. Thus, a newly designed Ascot and its sister vehicle Rafaga were additionally introduced in Japan, replacing the old “CB” Accord’s role and now being compliant with all favorable compact dimensions.

Styling the exterior of the 5th generation Accord was a challenge. During design talks for the 5th generation Accord, many of the stylists felt the 4th generation had been too conservative. They wanted to make the new cars sportier to attract new buyers. Complicating matters, however, others at Honda noted that the average age of current Accord buyers was increasing, and older buyers tend to like conservative designs. Honda did not want to alienate their current customers, but also needed to increase their customer base with a sportier, edgier exterior design that would appeal to a younger audience. So, in June 1990, Honda held a meeting at the Japanese Hotel Urashima with more than 100 people, which for the first time included key U.S. and European players early in the game to avoid communication problems. The U.S. design team unexpectedly presented a color slide show and video of their design concept. The Japanese were very surprised, but this head start soon developed into a friendly, but intense rivalry between all Honda design studios in America, Europe, and Japan.

Each team picked an image as a theme for their design entry, followed by sketches in July and a quarter-scale model in September. The Americans chose a shark and created a modern proposal with dramatically tapered sides and no grill. The Europeans used a cheetah for their image, which inspired their concept’s narrow window bands on a wedge-shaped body. The Japanese team started with a shooting star theme, but quickly changed to an American bald eagle that inspired their concept of a wing-like shoulder that swept along the sides of the vehicle. After sketches were shown in July, the Japanese again further revised their proposal using the American sketches for inspiration. At the September meeting, each studio leader presented their mock-up. The American shark concept was dropped after it was considered to contain too much American taste and be overly aggressive. In the end, the Japanese team won the design competition. Incredibly, the styling design for the 5th generation was decided one year faster than had been done for the 4th generation. The bald eagle look chosen was quite modern with a low, sleek frontal profile, but still displayed enough conservatism to appeal to a wider audience. The final exterior design proposal was a balancing act, a compromise between the sportier look and the conservative look.

The design team worked hard to ensure that the overall wedge shape appeared more seamless and flowing than that of the 4th generation, and also increased practicality. For example, window-molding seams on both sides of the vehicle were reduced for a cleaner look, while the sedan side rear windows no longer appeared as two separately divided sections, but were merged to increase visibility. On the front and rear, careful consideration was taken to make the bumpers larger for greater effectiveness but also integrate them more smoothly into the overall design. Moreover, detailed aerodynamic wind tunnel results, which were conducted to reduce noise, improve driving stability, and improve fuel economy, were integrated into the styling. These results helped shape the door mirrors, the large under-bumper front air dam, and side sills that gently curved up in the center, smoothly transferring air to the rear sills and past the vehicle. Even the curved side windows were crafted with maximum attention to detail and specially designed to allow water to efficiently drain upwards without stagnation and ensure complete visibility in the rain.

Nevertheless, as the new car’s development continued, problems emerged with the chosen styling. To save weight, a new lighter sub-frame had been designed to support the motor. However, this pushed the engine higher, so the low hood wouldn’t shut. In meeting after meeting, the Japanese design team defended their low frontal look, while engineering wanted to save the extra weight in order to add more safety equipment. After 3 months of battling, the designers finally gave in and the hood was raised. But this was not the end of changes to the front end. Engineers soon discovered an engine overheating issue attributed to inadequate cooling from the small grill. About this same time, in March 1992, Nobuhiko Kawamoto himself wanted to take one of the new prototypes for a spin around a Tokyo test track. When he saw the car outside, something bothered him. The nose, he decided, was too low and flat to balance with the body and would need to be raised upwards. After he made this decision, some Honda employees were furious with him. They had already raised the hood once. Fortunately, it only took two weeks to re-sculpt the clay model, raising the hood again by 3/4 of an inch and increasing the height of the grill by 1/4 inch. Looking at the redesigned front later, even the design leader admitted that the new frontal look was correct. Happily, this key decision also solved the engine overheating problem that was plaguing engineers. Unfortunately, tooling of course had to be re-calibrated, which added an additional month to the process.

Marketing also had their say in the design, influencing the look of the headlamps and taillights, and persuading Honda to adopt folding mirrors rather than cheaper fixed ones. They also promoted protective door edge molding that the designers had wanted to do without. Perhaps the most influential marketing change of all was in the sedan’s back door area. The designers, who had wanted a sportier and sleeker profile, had angled the upper rear corner on the back door sharply downwards, but passengers consequently brushed their heads against it. Marketing had to haggle with designers for over a year. Just 8 months before production, the designers – after studying competing car designs – finally agreed to raise the top of the door by 3/4 inch, which cost $40,000 in reprogramming tools. When all was finished, even with the late-running styling changes, the Honda designers only used less than half of the $14 million budget allotted to style the 5th generation.

In the process Honda paid close attention to improving the noise, vibration, and harshness (NVH) characteristics of the new 5th generation Accord. The three main targets included lowering engine vibrations, enhancing body rigidity, and utilizing more high technology damping materials. Through research, engineering found that the steering column presented a major interior pathway for low frequency vibrations. To compensate, engineers reinforced and extended the steering column hanger across the front of the vehicle from A-pillar to A-pillar. This raised the resonant frequency to a range less affected by driving vibration. To eliminate other low frequency resonances, engineers also redesigned and reinforced the passenger compartment central tunnel, upper dashboard, upper roof rail, front and center doorpost bases, and rear bulkhead. The rear passenger floors and C pillar, likewise, gained additional stiffeners. Compared to the 4th generation Accord, these changes reduced steering and seat vibrations by 5 decibels (dB). Engineering utilized additional high technology urethane damping materials, similar to the 4th generation, to further reduce noise and vibration without large weight penalties. This high technology material was now installed on the inside front pillars, dashboard, bulkheads, front foot wells, front and rear floor, wheel arches, shift quadrant, rear fenders, and trunk floor. These changes helped lower noise by an additional 3 dB on rough roads at low frequencies. Moreover, to lessen engine vibrations engineers re-used some other of the 4th generation’s technology. This included dual balance shafts on all inline 4 cylinder engines and vacuum-actuated liquid-filled active engine mounts with newly designed engine and transmission mountings. Honda also revised the exhaust system and air intake to lower vibration and noise. Additionally, all automatic transmission models received an extra stiffener to the lower cross member in the upper front bulkhead. These changes contributed to an engine noise reduction of 5 dB. To the amazement of some American engineers working on the 5th generation Accord at that time, the most experienced Japanese engineers actually tested for vibrations and excess engine noise simply by ear.

Honda took serious steps to ensure the 5th generation Accord’s rust resistance. Eighty percent of the sheet steel was galvanized, and Honda protected critical surfaces exposed to moisture by galvanizing both sides. In addition, Honda cleaned, degreased, and immersed every finished body in a zinc phosphate bath. Then, Honda submerged the bodies in a soluble electro-deposited primer. Afterwards, special sealants were applied to body seams and crevices and a special anti-chipping primer was added to areas of the body susceptible to stone chips or damage. Only then was an intermediate primer coat laid and followed by a polyester or acrylic resin top coat. For vehicles painted in metallic colors or pearlescent paints, Honda subsequently included an additional clear coat. To protect lower painted underbody components from rust, Honda also added chip resistant plastic resins on the sills, bumpers, and wheel arches. Being environmentally conscious, Honda tried to minimize its generated waste, so ground up and recycled any plastic bumper covers that did not meet their stringent quality specifications. The recycled plastics were later re-used for other components including interior air outlets, splashguards, and fuel tank covers.

Although one might see the 5th generation as a cheapened 4th generation Accord, this is not true. Honda instituted a new mantra called, “Value for Money” and included strict objectives to exceed the 4th generation in both safety and fuel efficiency. Honda did not compromise on these values. For the first time standard passive safety features included all of these: a flame retardant interior, front and rear crumple zones, high strength side impact door beams, a highly rigid occupant cabin with built-in door pad shock absorbers, and dual airbags on U.S. models. In addition, major effort was taken to reduce extraneous weight so engineers could re-enforce key areas for better collision strength. To validate the effectiveness of the new safety equipment, crash testing was also completed. Vehicles were tested in full frontal, full rear, side, angled, and offset barrier tests. Honda felt the new Accord should pass all crash tests, even those not mandated by governmental organizations. The new 5th generation Accord’s design met or exceeded them all.

Honda also offered additional active safety features including anti-lock brakes — and for high specification Japanese models, an optional traction control system or limited slip differential. With the additional passive and active safety equipment, the 5th generation weighed approximately 130 pounds more than its predecessor did. Nevertheless, Honda did not allow the weight increase to negatively impact fuel efficiency. In fact, one of the main reasons Honda believed the Accord was so popular was because of its fuel efficiency. Mr. Kawamoto who had previously been R&D chief engineer ensured that the current engineering team achieved his desired target of 12.5 km/liter [32.5 mpg] for the 5th generation sedan, even when current chief engineer Tomoyuki Sugiyama wanted to compromise. As Mr. Sugiyama stated, “If he [Nobuhiko Kawamoto] was a banker-turned-president, I could’ve deceived him, but he is an engineer. He knows what we are capable of.” Thus, Mr. Kawamoto got the fuel economy he wanted.

To cut unnecessary costs, Honda evaluated what had cost the company substantial money in the past. Honda identified that new part procurement typically cost 10% more for new models. To keep these costs flat for the 5th generation, Honda created a new Value Engineering Evolution Team (VEET) composed of senior engineers to evaluate each and every part before even allowing a sketch of a prototype part. This took extra time, but the VEET team held procurement costs flat and reduced post-prototype design changes by nearly 20% versus the 4th generation Accord.

Honda also identified significant manufacturing facility differences between Japan and America, which had cost the company considerable money redesigning parts when the 4th generation debuted. To assure that this would not happen again, Honda created the North America Task Group. This group of American engineers were flown to Japan with their families for 2 years strictly for the primary purpose of ensuring the new car’s design could be easily manufactured at Marysville, Ohio. This decision helped save millions of dollars. It also had the unexpected benefit of building good relationships between Japanese and American workers. In fact, often when discussing a topic, the two sides would end up dividing into production engineers versus design engineers instead of Japanese versus American. If a problem arose afterwards, American engineers would often just pick up the phone and take care of the problem directly with their Japanese colleagues instead of going through an intermediary. As one Honda employee stated, “The clouds have lifted,” which was good news for Honda.

Honda of America offered a myriad of trim levels on the 5th generation throughout its lifespan. At the 1994 U.S. introduction, Honda offered three 4-cylinder models: DX, LX, and EX. Coupes and sedans were available in all trims, but wagons were only available in LX or EX versions. 1995 dropped the DX coupe, but expanded the sedan line-up with the new flagship EX V6 sedan. The V6 sedan was outwardly distinguish by unique frontal styling, which previewed the 1996 facelift.

To quell U.S. dealer complaints that the 1994-1995 5th generation Accords looked too short, Nobuhiko Kawamoto authorized an expensive facelift for 1996 costing tens of millions of dollars that slightly lengthened both the front and rear of the 5th generation Accord. These 1996 mid-generation styling changes brought a more formal, upscale look to the Accord, while still maintaining an air of sportiness. The refresh included restyled taillights, a new grill, and front and rear bumpers to all trims, although wagons continued to feature pre-facelift rear taillights. Honda also introduced two new sedan trims in 1996 called the Value Package and 25th anniversary edition. The Value Package combined both DX and LX features, including DX rims and an LX type integrated rear window antenna with defroster, body colored rub strips, mirrors, and door handles. The 25th anniversary edition sedan was quite similar, but also included a badge on the rear trunk to commemorate Honda’s 25 years of selling automobiles in America.

For the 5th generation’s final year in America, 1997, Honda brought a new Special Edition trim to both sedans and coupes. Honda added many optional extras to the Special Edition, including a sunroof, cruise control, leather wrapped steering wheel, woodgrain-like center console, factory keyless alarm, and special alloy wheels, along with a unique special-edition badge on the trunk. For the wagons, which had unexpectedly proven over the past years to be more popular in the Japanese market than the U.S. market, the 1997 5th generation Accord was the last Accord wagon sold in the U.S.

By 1985, Honda of Japan had split up their car dealerships into three distinct entities: Honda Verno, Honda Clio, and Honda Primo. Each chain carried certain models and sold vehicles under a unique theme. Honda Verno sold sporty products. Honda Clio offered luxurious models. Honda Primo sold regular family vehicles, as well as motorcycles and power equipment. Until 1989, the Accord was sold in both Honda Primo and Honda Clio stores. In 1989, Honda decided that Honda Clio should be the exclusive Japanese distributor of the Accord. Thus, the wider 5th generation Honda Accord was marketed strictly through the upmarket Honda Clio dealerships. With their higher prices and wide bodies, 5th generation Accords were not expected to be popular with Japanese clientele, and they generally were not. Part of my family is Japanese, and they confirmed that Japanese Accords of this generation were considered big, luxurious vehicles and could become very expensive to keep. That is why I rarely saw 5th generation Accords when I visited Japan in the 2000’s. On the other hand, the American perspective of the 5th generation Accords was that they were considered reliable everyday transportation, and were not really luxurious or expensive to maintain. Still, in both countries current owners are usually enthusiasts who cherish their 5th generation Accords today.

The Accord sedan was introduced to Japan in late 1993. Japanese market sedans were produced at the Sayama plant and were available in 6 models: EX, 2.0EX, 2.0EXL, 2.2VTE, 2.2VTL, and SiR. Model differences included power plant choices and interior appointments, with luxury increasing corresponding with engine displacement. This logic helped to encourage buyers of larger engine vehicles who were perhaps hesitant because of the significant disadvantages of higher tax rates and ownership costs. EX models received the base 125 hp 1.8-Liter SOHC engine and offered a standard, plain cloth interior with few amenities. 2.0EX and 2.0EXL models acquired the 135 hp 2.0-Liter SOHC engine and received additional standard features like keyless entry and a genuine woodgrain center console. 2.2VTE and 2.2VTL models were given an even more powerful 145 hp 2.2-Liter SOHC VTEC engine and offered unique items unavailable on less expensive models like the VTL’s leather wrapped steering wheel. The flagship SiR model utilized the top range 190 hp 2.2-Liter DOHC VTEC engine and was the sole sedan available with either a manual or an automatic transmission, with all other lower tier variants being strictly automatics.

1994 brought two special edition Japanese sedans based on 2.2-liter models called the JCOTY Memorial Prize and Grand Stage. The JCOTY Memorial Prize edition came in a unique blue color with special badging and was priced similar to regular 2.2-liter variants. However, the Grand Stage edition cost approximately 20% less than comparable 2.2-liter models, but included special wheels, a leather wrapped steering wheel, rear cup holders, chromed grill, and front mud guards. A new 2.2VTS model was also introduced late in 1994 and was externally almost identical to an SiR model but was only offered with an automatic transmission and the 2.2-Liter SOHC VTEC engine.

For late 1995, Honda was keen to increase their domestic sales volume that lagged behind other established Japanese automakers. Thus, Honda introduced a lower specification Japanese Accord sedan called the EF to entice buyers. The EF’s price was kept deliberately low by offering only a base 1.8-Liter SOHC engine with a less expensive interior that adopted manual HVAC controls, replacing the standard automatic unit. At the same time, Honda also broadened the availability of their 5-speed manual transmission, offering it in both lower and higher end models. In mid-1996, the EF was replaced by a slightly higher trimmed model, the 1.8 EX II, which had body color-matching mirrors and door handles, unlike the EF. None of the strategies worked for Honda, and Accord sales remained firmly stagnant in Japan for 1996, accounting for a mere 7.2% of sales versus 45% in America. Nevertheless, Honda endowed the Japanese Accord sedan throughout its run with some unique touches, distinguishing it both stylistically and regulation-wise from the rest of the world. This included an optional door guard delete, no rear side markers, and standard front fender mounted turn signals.

Honda of America in Ohio exclusively produced 5th generation wagons and coupes, some of which were built for export to Japan. Honda was proud of the American involvement, and Japanese commercials and brochures proudly emphasized their American origins. Coupes came in 2 models including a lower 2.2 Vi trim and a range topping SiR. The 2.2Vi had the 2.2-Liter SOHC VTEC engine and was available in both left- and right-hand drive configurations. Although Japanese domestic vehicles are normally right-hand drive, left-hand drive was offered because it was and still is considered a cool and trendy status symbol in Japan. Left-hand drive models were differentiated from right-hand drive models by utilizing different dashboards. The American dashboard on the left-hand drive models came with manual air conditioning controls, as opposed to the right-hand drive versions which offered standard automatic climate control. SiR coupes came strictly with the range topping Japanese-built 2.2-Liter DOHC VTEC H22A engine, anti-lock brakes, a Bose-tuned audio system, sunroof, and cruise control but were right-hand drive only.

Japanese wagons were also available as strictly right-hand drive units and used the 2.2-Liter SOHC VTEC engine with two initial models, the 2.2Vi and 2.2VTL. This four-door wagon with its sporty, shooting-brake curved rear body, glass, and tailgate was well received in Japan and was the best-selling import car for 1994 and 1995. Its chic looks successfully enticed Japanese buyers and caused the wagon to outsell other Accord variants by 4:1, creating a customer waiting list for this body-style. Thus, in 1996 Honda brought a new mid-range 2.2ViX wagon to the model line. By 1997, the 2.2VTL wagon was dropped and Honda introduced a new, hotter-grade SiR wagon with the same SiR coupe 2.2-Liter DOHC VTEC H22A. Honda also endowed the SiR wagon with a unique platform designation, “CF”, specifically for this model.

The Japanese 5th generation Accords had a few unique peculiarities. Like most Japanese market vehicles, airbags were optional on less expensive 1994-1995 models, with only more expensive models receiving a standard driver’s side airbag. Dual airbags became standard for 1996 in all Japanese models. Coupes and sedans received the standard dual airbags in January and July respectively, while the more popular wagons acquired them in September. To help distinguish the American-made wagons and coupes from their Japanese-made sedan counterparts, special Honda of America badging showcasing an American eagle was installed on the C-pillars. Being luxury-oriented products, Japanese coupes and wagons also came standard with an automatic transmission, regardless of engine, unlike America where both manual and automatic transmissions were available. Both Japanese specification coupes and post-facelift wagons built in Marysville, Ohio, also featured standard American rear side markers, which were promoted as an additional safety feature in addition to the mandatory Japanese front fender turn signals.

Japanese exported coupes and wagons did not have a standard sixteen-digit vehicle identification number at the driver’s side base of the windshield. In its place, a plaque reading Honda of America MFG., INC. resided on the windshield, with the Japanese VIN located under the hood. Another Japanese model distinction not readily discerned was an Onboard Diagnostic (OBD) computer change for 1996. Although all American models received standard OBD II electronics that year, Japanese models received an unusual hybrid arrangement with an OBD II plug backed by modified OBD I electronics. Of course, Japanese-only accessories were offered throughout the Accord line, including custom wheels, parking sensors, a factory navigation system, cornering lights, bumper mounted parking poles, graphic kits, and Honda branded roof racks.

The interior of the new 5th generation Accord was very inviting. It felt upscale and utilized many soft touch materials. Unlike the monotone plastics of many 90’s rivals, this generation Accord introduced standard two-tone color combinations. The new wrap-around interior design incorporated a darker color for the top of the doors and dashboard, specifically designed to reduce the sun’s glare and create a sense of comfort and serenity. Despite a shorter overall vehicle length than the 4th generation, usable interior space improved with better shoulder, head, and leg room. Front and rear seating was also revised to ensure optimum posture, fit, and support for all types of driving. Once seated in the cabin, a newly designed instrument panel greeted the occupants. Its design was true ergonomic excellence. For the driver, the large speedometer and tachometer were placed directly in their line of sight, with other gauges easily readable at a glance.

Other standard interior equipment included interior trunk release, HVAC controls, ashtrays, cigarette lighter, gas door lever, digital clock, and radio with cassette player. These were easy to read, intuitive to use, and felt natural to the hand. The user friendliness of all interior accoutrements, including optional extras like cruise control or CD player was no accident. Honda spent much effort re-evaluating the reach of each cabin switch and button to ensure optimal ease of use. Another notable improvement for the 5th generation was better in-car storage including a large center console box between the front seats, an easier to operate glovebox, and a small storage cubby on each side of the front door panels. Even beverage storage was not neglected and new, sturdier, better-integrated cup holders were designed and relocated in front of the center console box for easy reach. Looking closer, Honda also provided other thoughtful interior touches including standard rear door child safety locks, and specifically on sunroof models, a small hole in the headliner covered by a plastic disk that allowed closure of the sunroof with a specially supplied tool if power was lost.

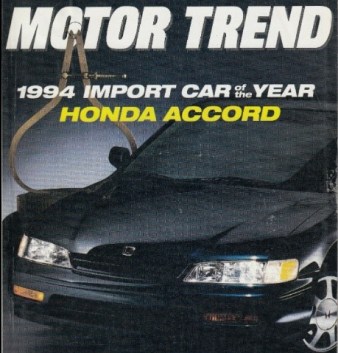

The careful balance of cost accounting and engineering prowess in the new 5th generation Accord paid off. The code name for the new Accord was CY for Car of the Year, and it lived up to its hype. The 5th generation Accord won both Japan’s Car of the Year and Motor Trend’s Import Car of the Year awards. Head Honda CEO Nobuhiko Kawamoto even drove a new Accord himself to the Japanese awards ceremony, causing quite a stir among the other chauffeur-driven Japanese automotive executives who arrived.

This 5th generation is also notable for being the first Accord badge-engineered car as an Isuzu passenger car, the Aska. The Aska nameplate had denoted Isuzu’s top passenger sedan for 10 years. In the past, the Aska had been a modified GM J-Car or a badge-engineered Subaru Legacy. After those deals ended, Isuzu dealt with Honda, providing sport utility vehicles in exchange for Honda’s passenger cars. The new Aska was a thinly disguised Accord with only minor differences like grill trim and badging. Models included the LF or LJ, and came with a limited color range and only the one choice of a 2.0-Liter SOHC engine. In the past with GM, Isuzu had been allowed to create special sporty versions of the Aska. I can’t help but wish that Isuzu had done the same with Honda and created a Handling by Lotus or Irmscher-tuned Accord-based Aska.

After all the effort in creating Honda’s new benchmark family car, the 5th generation Accord came close, but did not dethrone the Ford Taurus sales in its first three years. However unlike its predecessor, 5th generation Accord sales rose fairly steadily year after year in the U.S and — somewhat unusual for an old model — the 5th generation’s last year in 1997 showcased its best sales. With it, the Accord finally dethroned a redesigned Ford Taurus. However, it snatched defeat from the jaws of victory as it still came in second to the Toyota Camry. Nevertheless, the 5th generation had a solid sales history and attracted younger buyers to the fold, thus achieving Honda’s goals. In fact, over a quarter of a century later, the 5th generation Accord is still one of the most desirable cars in America, being on the list of the top 5 most stolen vehicles as recent as 2020. How many quarter-of-a-century old designs can say that?

If any of the team who helped create, build, or service the 5th generation Accord is reading this article, I would like to say one thing, thank you. Your car saved the Honda Company by making a profit while refining and actually improving the outstanding 4th generation. Over 25 years after this car’s production ended, its excellent design and thoughtful engineering still make me thankful I own such a wonderful 1996 Accord, purchased brand new, but now with over 200,000 miles and still utilized and depended on daily. To me, the 5th generation Honda Accord is truly the ultimate Accord. It showcased the perfect balance between advanced engineering geared toward customer satisfaction and the equally important cost savings that allowed Honda to make a profit in hard times. In fact, the word “Accord” means an agreement, and that’s what happened here. I don’t think Honda has replicated as perfect a balance since. But hopefully Honda will keep trying to achieve an even better balance. After all that just might be what an Accord is all about.

EXCELLENT write-up.

In 1988-89, when I went looking for a car to replace my 82 J2000 I shopped the American brands and then Honda. Until that point I had been very resistant to the idea of buying a new car from a foreign manufacturer figuring my money should support the local workers. But the Civic I eventually bought, while more expensive and with fewer ” gimmicks ” was a much better engineered car. I convinced myself that it made more sense to buy a better engineered car that was a little more expensive than it’s rivals than to pay less and always feel like I got a cheap car/no real bargain.

Until about 2000 I always thought Honda put engineering at the top of the priority list, but at the dawn of the 21st century things changed at Honda. Apparently? Things changed much sooner than I thought.

Honda does NOT currently sell a 4 wheeled vehicle in the U.S. that I would want to own. The styling is….? And while the engineering is good, it covers such hideous vehicles.

I agree Howard. My family used to be Honda nuts, having worked our way through a series of increasingly less-worn out Civics since immigrating in 1992: an brown ’82 5spd Wagon bought for $750 from my dad’s coworker that lasted a year or two, then a tan 5spd ’85 Sedan bought from the local Honda dealer’s used lot (got totaled by a firebird that rear-ended my parents in traffic), then a brown ’90 Civic Wagon bought from the same Honda dealer’s used lot after a deal on a private seller’s ’87 RT4WD Wagovan fell through, along with our $50 deposit. Had the ’90 for 12 years, then the new for 2007 Fit came to US shores and we were finally ready to upgrade. Sold the ’90 and bought a base 5spd Fit, all the way out in Patterson NJ, for MSRP. The Fit was obviously a much more modern car, rode better, it was a 5spd versus the ’90s auto. But it was a very cost cut, lesser engineered car compared to that 1990 Civic. Mac-struts with torsion beam rear end versus 4 wheel independent with double wishbones. Much “tippier” handling, worse visibility. A very cheap interior (hard plastics, cheap upholstery). Still a very nice runabout, but a lot of the magic was gone. I still ended up buying a 2012 Civic out of college, a 1 year old used one, basic LX sedan with a manual. Perfectly nice reliable car, but it was again just a competent driving car, lacking the old Honda “jewel-like” qualities that made them feel special. At the very least the engine was laser smooth and the shifter was excellent (notably better than our Fit’s shifter). My friend bought one of the new gen 2017 Civics with the CVT+1.5 turbo. This was when they finally became wholly unpalatable to me. Quality had gone down even further, notably worse than my 2012 (uneven stitching on seat upholstery, awful neoprene style seat fabric, uneven panel gaps, a few random issues with wipers and a suspension clunk within a few years of buying it).

I can’t see myself buying any new Honda anytime soon.

Modern Honda is a marketing- and sales-led organization, rather than the old engineering-led structure. One of my favorite little asides was the mid-cycle refresh of the 2016 Accord. The wheel sizes increase an inch across all trim levels, obviously a marketing-led decision to follow market trends. This gave every model less sidewall to work with, hurting ride quality by necessity, which engineering then countered (on an already in production design, so no ability to clean sheet this) by replacing front and rear subframe mounts with more expensive and failure prone hudraulic fluid filled mounts. And the big response from every automotive rag when they reviewed the updated car? It rode worse across all trims than the pre-refresh models. But sales didn’t reflect this more negative view, as they increased. Unfortunately, the realities of the market have rewarded this type of behavior for many manufacturers (even modern day Toyota follows market trends more than total quality investment), while discouraging engineering choices. Very similar to the decline of the art of film making in favor of sales-driven safe bet blockbusters. Modern Hondas aren’t thinking people’s cars anymore, more like slightly better than average quality lease deals with some brand cache remaining from the total quality days. They make just as many engineering mistakes as GM or Ford now, with their terrible panel gaps, keyless start issues on the V6 cars, oil diluting 1.5t, body integrity screw ups on Odysseys and Pilots, utterly bewildering product planning at Acura, self destructing J37 V6s, last gen Civics with crazy R1234yf A/C issues (which often were denied even new car warranty coverage), use of the garbage ZF 9 speed automatic, which eclipsed even the post-H4A Hondamatic for huge failure rates, and major electrical and interior electronics issues across most of the bigger Accord platform vehicles, their reliance on the dual screen control set up in last-gen Acura models, and probably a few other things I’m forgetting. All problems from the last decade, and most from the last 5 years, as they transition from total quality engineering to a cost-effective engineer model, with quality targets moving from “best possible” to “market competitive for the lease period.” But again, they are mostly following the market and spending money where it’s reflected on a balance sheet or sales report. Some of us just still hold a more nuanced view of things.

I won’t even mention their plans to rebadge GM-sourced EVs from the former Saturn Spring Hill plant as their US-specific EV product development plan. The Honda that developed this 5th generation Accord isn’t with us anymore.

“last gen Civics with crazy R1234yf A/C issues”

I forgot to mention, on the friend’s 2017 Civic, wonky A/C is the latest issue in a string of quality problems.

I helped him buy a used 2004 Accord EX-L for his fiance a fwe months ago and I think he likes driving that older Accord more than his decade+newer Civic.

A friend and coworker bought a 5th gen Accord Coupe – the first new car she’d bought for herself – I don’t recall the exact year but it was a very nice car for the money, leather and a sunroof but with a 4 cylinder and A/T power train. I drove it a couple of times, rode to lunch in it a bunch (both front and back seats – roomy for a coupe) and often thought a manual transmission version with a V-6 would be a hoot – her 4 cylinder version was fun to drive but a little lacking in power. If it’d been a V-6 I’d have bought it from her at trade in time…

Thank you for this impressive history. Although I never found the styling of this generation as appealing as that which came either before or after, I knew that they retained traditional Honda virtues. The styling did give the impression of a smaller car. I had not known about the cost-saving efforts that had gone into these.

I also recall that this was the generation which had to face a Camry that was really coming on strong. Toyota seemed to embrace the V6 engine, while Honda always seemed to treat it as a high-end luxury product. The V6 became a real need in the US market of the 90s, but Accords seemed (at least from my observations) fairly rare in that configuration. And were the transmissions mated to the first V6s bad from the start?

Awesome piece! This type of content is part of what makes CC such a gem!

I’ve had a decent amount of experience with both 4th and 5th gen Accords, enough to have some thoughts on differences and likes/dislikes between the two. I’d say the 5th gen interior, while still very good quality, feels a bit cheaper than the 4th gen. Something about the dash being a bit “simpler?” and just a few individual pieces or materials feeling a bit cheaper. 5th gen feels notably wider inside. On rustproofing, it seems like pre-facelift 5th gens (94-95) still had the typical Honda rear quarter panel rot, but then for 96-97 they did something to minimize this dramatically. To the point where I see a lot of 96-97s that are still basically rust free. Both 4th and 5th gens have the silly “hub over rotor” brake design where replacing a rotor requires separating the lower balljoint. A pain in the butt for the DIYer, and does balljoint longevity no favors.

“Notably, the H4A transmissions proved to be one of Honda’s last heavy-duty automatic transmissions. Compare the difference in failure rates between these units and the medium-duty 6th generation automatic units, especially the V6 variant, and the results are startling. The H4A is clearly a more rugged transmission.”

Would be curious to hear more specifics on this. Were “heavy duty’ and “medium duty” actual internal designations? I had always assumed it was a combination of retuning for smoother shifting (ie more slip and therefor heat buildup) as well as increasing weight of the cars and power of the engines that lead to the transmission failures, in particular in the hotter V6 cars. I definitely remember the firm shifting of the older Honda 4spd autos, and I definitely suspect this helped with longevity. I never minded it too much, it was just part of the Honda “sportiness,” although to really enjoy Honda sportiness, you’d want to get their excellent 5spd manual.

Well that helps unravel the badge soup this era of Hondas come in and to make matters worse all variants you mention are on the roads here or were they are aging out of use now as inspection failures and other issues take them off the road.

had the 1996 wagon – it was a five speed

had it for 17 years – no rust on body

car started leaking gas from the tank – Honda dealer said ethanol mix gas destroyed the tank and would cost $4000 because the rear suspension would have to be removed to do it

the wagon was 4 inches longer than the sedan and had an Acura rear suspension and Acura brakes – it was the most expensive Accord

the steel on the body was much thicker than previous gens

Great write-up, very interesting!

This gen 5 Accord is the last one that really impressed me. Though it was bigger than the gen 4 (which was a tad bigger than gen 3, my favorite), I liked the sleeker styling, and I liked the interior a lot (even though the driver’s seat didn’t quite feel right).

A lot of good history here.

It hit the US a few years after the 1992 Camry, where I read some Toyota exec famously remarked “we gave too much away on that car”.

A female friend of mine at the time was new car shopping to replace her Plymouth Sundance (which she disliked intensely… “no more American cars!”) and narrowed it down to a 94 Camry or a 94 Accord. I told her they were both excellent cars–I would have taken and Accord 5-speed. She wanted an automatic, so I told here if she wanted a little more quiet and smoother ride, get the Camry. If you want a sportier, more “fun” car, take the Accord. She got the Accord, which she obviously liked, as she replaced it with a “newly introduced” Passport, and years later when our paths crossed, had a Honda mini-van.

But personally, I’m with @gtemnykh now, and have been for some time. The looks of the Civic…. and my perception of Honda’s quality….ouch. I’ve gotten older too–now my next, perhaps last NEW car, if I had to get it today would be a….Camry, lol

I would certainly agree that the 4th generation was “peak” Honda Accord.

Excellent writeup. In 1994, my father was looking for a new car to replace his 83 Olds’ Cutlass Ciera. He was looking for a corolla. However, I was able to convinced him to purchase a 94 Accord. Believe it or not, the price of a Corolla was only a little bit lower than the Accord DX.

There was an issue shortly after the warranty expired. One day, there was a good amount of motor oil on the garage floor underneath the engine due to the infamous rear main seal leak. However, despite for not being a recall, Honda reimbursed the towing and repair bills.

Since then, it had provided many years of reliable ownership. It was the last 2 years when part failures were starting to occur. However, the car is relatively simple to work on. So it lives on for now.

My best friend bought a 93 Accord EX new. I loved his Accord. In fact, I preferred the 4th gen styling. Interior wise, I don’t recall the 4th gen having any real advantages over the 5th gen. But my memory is obvious faded. Anyway, both great cars.

Great and thorough write up. I always thought the 4th gen had perfect proportions, and taillights of the 5th generation looked too much like an Oldsmobile of the era. Meanwhile the Camry went from slightly too large headlights to too narrow taillights. Meanwhile we were a happy Mazda and later Acura Legend family.

Thanks for this excellent look at this generation, which marked a turning point at Honda (and other Japanese brands). No longer could they maintain their previous cycle of new or substantially new generations every four years. How Honda pulled this off was remarkably effective, although stylistically, I preferred the 4th generation. So for me, that’s still peak Accord.

But you’ve made a very compelling case here for the 5th.

Agree on the styling of the 4th. Distinctive but still discreet, if that makes sense. Everything the last few generations of Civic were not, though perhaps Honda styling is trending in the right direction (for my tastes) again.

I always thought the 4th gen looks very elegant with the metallic grey color while the 5th gen looks terrible with that color.

I had both an automatic ’95 Accord wagon, VTEC, and a ’94 auto Camry sedan, V6. The Honda handled much better while the Camry was more reliable and had a more comfortable interior. Both could tackle mountain passes with ease and the Grade Logic Control in the Honda actually did shift down into third gear when descending steep grades.

Great write up!

I knew this was a perfect car, but the styling was not memorable. The Accord looked too small and it was a challenge to see one without thinking it was a Civic. It was a peak, like the Oval Taurus was a peak – a peak that didn’t look like one, except in hindsight. But that is how it goes with the auto market – you don’t know you are at the top until you are no longer there.

How absolutely fascinating. I love the behind-the-scenes insights you have given us, and how the American and Japanese engineers worked together, and were able to deal with problems without an intermediary.

Fancy being able to develop both the wide-body ‘US’ Accord and the narrow-body ‘rest-of-world’ version, both seemingly uncompromised, and still come in under budget. So often we read of things going over-budget and still off-target.

Like some others here, my favourite would be the previous generation, but now I have a much greater appreciation of what went on to develop this one.

Another one to bookmark to read again!

Honda didn’t really do another new platform other than the true CD cars, however. Japan’s Ascot/Rafaga was a shrunken wheelbase narrow-body CB Inspire/Vigor with new styling (CE4/5; longitudinal engine layout, not related to the subject article CE wagon), which along with the CD Accord, were sales bombs. The idea was that the well respected Accord name would translate into sales in the luxury sector where the previous Inspire/Vigor faltered. It did not. Honda did not try this dual strategy route in Japan again, and reverted the Accord back into the compact class for the following generation (the success of the UA Inspire/Saber introduced in 1995 likely made this possible). Honda took an even more economical route for Europe; they quite literally recycled the previous generation JDM CB Ascot Innova (also an underwhelming seller in Japan) with the addition of framed window glass. Honda made sure to extract their money’s worth from the development of the CB, that’s for certain.

I have a 97 4 door in my garage. Timing belt broke. So I decided I was going to put in an h23 in it. I haven’t done a THING! Been a year now. I hope I do it and not quit

A impressively detailed write up. I think this is the best looking Accord, along with the 7th generation Accord Euro/Acura TSX (although the latter had a horrible dashboard IMO).

However the wagon version looks like an aftermarket conversion. All of the ones sold in Australia were automatic. I wasn’t aware the US had the V6 versions, but am aware of the coupe.

I nearly bought a used manual 2.2 VTIs (the top model here) and although it was a very nice car it didn’t fell nimble or dynamic enough for me and I backed out of the deal. If it had been like the DOHC JDM Sir version, I would it might have been a different story.

I eventually bought a Civic VTiR hatch, which although it was very jewel like and reliable, it was somehow also felt boring despite that high redline. I haven’t owned a Honda since and the current models leave me cold.

Since 2011 and running strong.

We didn’t get this 5th gen Accord in Europe – we got a British built version of the Honda Ascot, which was the Accords’ Japanese cousin. A few Accord Coupes were imported from the USA though, which was confusing, as they looked so different.

Got a 98 ex with a 2.3l vtec and 5sp…. 315000 miles as of now and counting. Great car. Sure there’s issues but I still love it!

This is very good article. In my view, it is better than most of car magazine articles we have these days.

I always like Accord — I owned two 87 3rd & 03 7th, another two Honda products, 1992 Interga and 15 Odyssey. For regular people, we can’t get than owning a Honda, affordable, reliable, economical, enjoyable and safe. If you get a chance to drive another band products, you will know how Honda is. Accord is the car which Honda is today, sadly to say Honda may stop making it soon.

So happy to have found this detailed, well written article!

I have owned a 4th gen 1992 Accord EXR (Canadian version of the fully equipped Accord) since 2009. I have stored it every winter and have been babying this jewel for the last 12 years. Love driving it with the sunroof down and the music blaring-makes this 51 year old feel young again.

In December 2021, I sold my gas guzzling, powerful, but fun to drive 2013 Infiniti G37x and purchased a 1 owner 1997 Accord EX (Canadian spec) with 106 000 kms on it. Rust free and pampered throughout its 25 years and equipped with an alarm system and remote starter. I was amazed at how much quieter and more nimble the 97 Accord is than my 92. I pushed the 97 to 140 km/h on my test drive. No shakes or rattles and it hugged the road beautifully on cheap, old winter tires. Unbelievable build quality! My conundrum now is that I realize the 1997 Accord is worth safe guarding as much as my 1992. I just don’t have the means to store both and buy a winter beater.

This article reinforced that I made a wise purchase.

This is Shimada from Honda Motor Co., Ltd.

I would like to contact you directly, so please let me know your email address

Please contact me at piersona117@gmail.com

I would like to thank you for the letter I received at the Collection Hall in Motegi. I’m very sorry, but could you please send me an email?

Please give me your email address and I will send you an email.